9. Bio-based aviation fuel

9. Bio-based aviation fuel

This book is about advanced fuels based on agricultural biomass resources and their production.

9.1 Which bio-based fuels are already available?

Bioethanol and biodiesel are among the most widely used biofuels and are mostly used in road vehicles or blended with conventional fossil-based fuel. Bioethanol is produced via a fermentation process with subsequent distillation. Currently, the main raw materials used are corn (in the USA) or sugar cane (in Brazil). Depending on the production process and raw material basis, a distinction is made between FAME (fatty acid methyl ester) and HVO (hydrognenated vegetable oil) or, synonymously, HEFA (hydroprocessed esters and fatty acids) in the case of biodiesel. FAME has a different chemical composition to fossil diesel and is therefore not suitable in its pure form for conventional diesel engines and is therefore only blended in. HVO and HEFA, on the other hand, are fully compatible. If you want to learn more about the different production processes and raw materials, you can take a look at chapter 2 of the educational material on the topic of future-oriented fuels on the HOOU platform.

Classification of biofuels

Biofuels can be divided into 3 types, which are also referred to as generations. The characterization depends on the raw materials used and the level of their technological maturity:

1st generation fuels

- Conventional biofuels

- are based on sugar, starch or vegetable oil, i.e. biomass that is also used as food

- the production process is well mastered and is already widely used and commercialized

2nd generation fuels

- are based on cellulosic biomass (e.g. wood, straw or maize straw)

- do not compete directly with food production, but still require land resources

- the processing technology is sometimes immature and costly, as cellulose-containing material must be pre-treated before conversion

3rd generation fuels

- use special microorganisms such as algae as raw materials

- Algae are a large group of photosynthesizing organisms with around 30,000 known species

- Biofuel production from algae is well established on a small scale, but not yet economically feasible on an industrial scale

There is now also talk of a 4th generation of fuels. This refers to biofuels that are produced from genetically modified algae or plants. Genetic modification can eliminate the disadvantages of “normal” plants, such as a low fat content or low growth rates.

In some cases, hydrogen from renewable sources, biomethane, synthetic biofuels and fuels from renewable electricity, sometimes in combination with carbon capture and storage, are also referred to as fourth-generation fuels.

Status quo production

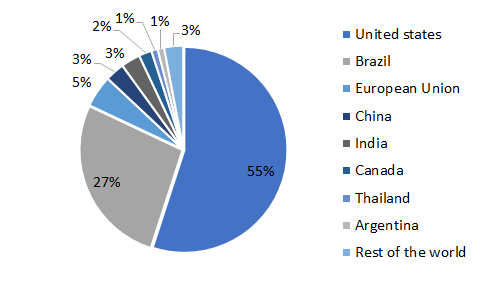

Im Jahr 2021 wurden 159 Milliarden Liter Biokraftstoffe produziert (IEA, 2022). Große Mengen der derzeit verwendeten Biokraftstoffe werden aus Pflanzenölen gewonnen. Bioethanol ist der weltweit am häufigsten verwendete Biokraftstoff. Im Jahr 2021 wurden weltweit ca. 103 Mrd. Liter produziert. USA, Brasilien und die Europäische Union sind die größten Erzeugerländer (Renewable Fuels Association, 2022: ).

Global production of biodiesel and biokerosene is significantly lower.Around 54 billion liters were produced in 2021. The production of biodiesel through transesterification (FAME) accounted for around 80% of this volume, while hydrogenated biodiesel (HVO and HEFA) only accounted for 17%.

HEFA technology is currently used in most cases for the production of SAF (Shahriar & Khanal, 2022: ).Waste fats, oils and animal fats are used as raw materials. Biodiesel production using the alcohol-to-jet process from municipal waste or forestry and agricultural residues is much lower (Shahriar & Khanal 2022).

In 2021, however, only 0.1% of global kerosene demand was covered by SAF. According to the IEA (2022), the share is expected to increase to 5% by 2030.

Aviation fuels

Aviation fuels must meet very specific requirements in terms of combustion quality and safety.

The fuel must:

- not ignite uncontrollably

- not form deposits

- not become electrically charged

- not freeze at temperatures below -30 °C

Of course, these requirements also apply to bio-based aviation fuels.

The term SAF - Sustainable Aviation Fuel - has been used for some time by the aviation industry for alternative fuels based on biogenic raw materials and also includes electricity-based fuels. At present, however, these SAFs are not used in their pure form, but are blended with up to 50% fossil kerosene.