8. Biogas production

8. Biogas production

Learn about the biogas production process in this book.

8.2 Processes in biogas production

The basic principle of biogas production is simple: substrates that can be degraded by methane-producing microorganisms (methanogenic archaea) are fed into a fermenter and heated. As the methanogens cannot tolerate oxygen, the fermenter must be airtight. The biological decomposition processes produce methane, which is purified and can be burned in gas turbines to generate electricity or heat.

The production of methane (methane fermentation) is mainly carried out by bacteria that live without oxygen. It is an anaerobic decomposition process that also takes place in bogs, for example. The gas produced consists mainly of methane (CH4) and carbon dioxide (CO₂). Not just one type of bacteria is involved in the process. The different strains are dependent on each other and each carry out sub-steps of the degradation process. The initial substrate determines the composition of the bacterial community, with the bacteria with the lowest growth rates limiting the speed of degradation and thus methane formation.

The methane formation process

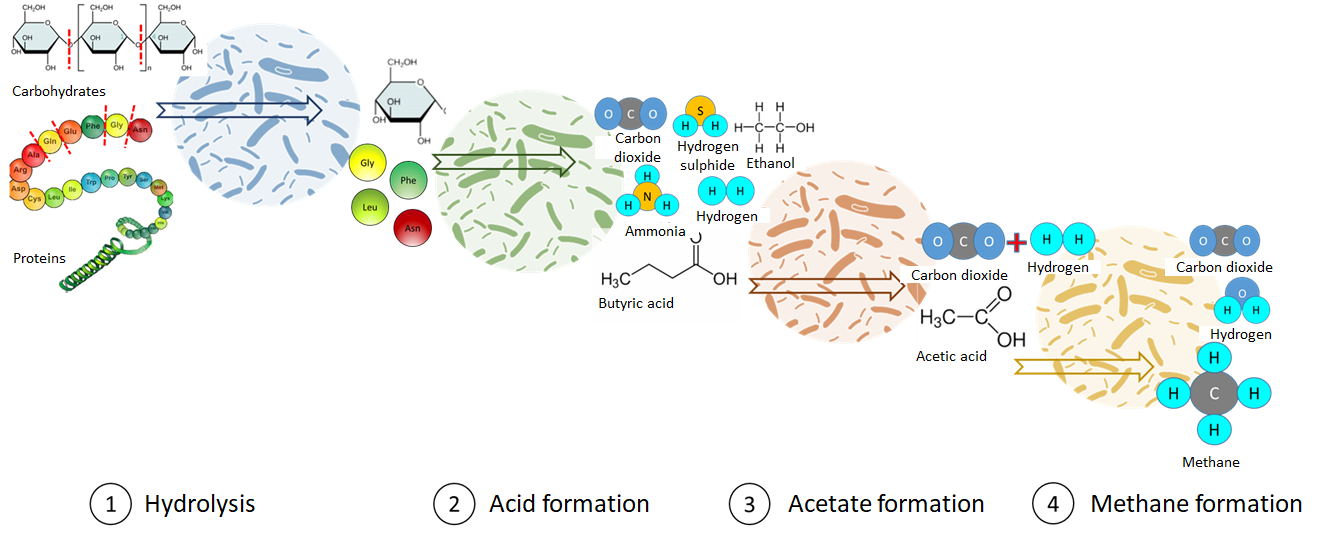

In general, a distinction is made between four sub-processes, which do not take place separately, but in parallel in terms of space and time.

1st step = hydrolysis:

Breakdown of polymeric organic components (proteins, fats, carbohydrates) into small water-soluble monomers (amino acids, fatty acids, mono- and disaccharides). The degradation rate of the components usually also determines the speed of the overall process. Cellulose, for example, is more difficult for microorganisms to break down.

2nd step = acidification:

Acid-forming, facultatively anaerobic bacteria metabolize monomers into short-chain carboxylic acids (butyric or propionic acid), alcohols (ethanol) and gases (CO₂, H2, hydrogen sulphide and ammonia)

3rd step = acetate formation:

Acetogenic, heat-loving bacteria convert the carboxylic acids into acetic acid, hydrogen and carbon dioxide

4th step = methane formation:

Methane bacteria (archeobacteria) break down acetic acid in an anaerobic environment or reduce carbon dioxide using hydrogen. Methane is formed 70% from acetic acid and 30% from the reaction of carbon dioxide and hydrogen.

Conditions in the fermenter

A constant temperature should prevail in the fermenter. Rapid temperature changes disrupt the development of the microorganisms and destabilize the process. The ideal temperature for the development of microorganisms is 36-38 °C. The highest gas yields and stable operation are achieved in this mesophilic range. However, there are also fermenters that operate at ambient temperature (<25 °C) or in the thermophilic range of 50° to 60 °C.

Although the methane-forming microorganisms are sensitive to oxygen, contact with oxygen can never be completely prevented in practice. However, since oxygen-consuming bacteria also live in the fermenter, the oxygen is used by them before it can damage the archaea. However, too much oxygen must not be allowed to enter the fermenter.

The pH value should also be set correctly. A pH value of 7 is ideal. Acid inhibits the development of methane-producing bacteria and pH values that are too high (> 8) have a toxic effect. The pH values are mainly determined by the substrate. If the fermenter is overfilled due to an incorrect ratio of substrate supply, temperature and microbial activity, acidification can occur.

Helpful information for planning a biogas plant can be found here.

Residence times

- depending on the substrate

- for short periods of time, only easily degradable substances are methanized

- with longer periods, medium to poorly degradable substances are also methanized

- longer residence time means higher gas yield per kg of biomass

- the residence time also depends on the reactor volume

- however, complete degradation would take a very long time and require large plant volumes

- an optimum degradation performance should therefore be found

- Important key figure for the dimensioning of the plant: OLR organic loading rate (in kg oTS/m3 x d) - possible supply of organic dry matter (oTS) per time unit and reactor volume

- the higher the room loads and lower the substrate concentration, the lower the retention time in the reactor

- highest gas production rate at the operating point of the smallest practically possible residence time that can be operated stably