7. Biorefinery concept

7. Biorefinery concept

Find out everything about biorefineries in this book.

7. Biorefinery concept

Biorefineries try to extract as many valuable substances and products as possible from biomass using a technical system. With this zero-waste approach, they represent the concept of the bioeconomy in perfection. The product range extends from chemicals to biofuels.

What you should know:

- Biorefineries use various chemical or physical processes to break down and refine biomass

- some biorefinery concepts are still at the experimental stage, others are already in commercial operation

- Commercial plants often produce biofuels as their main product

- Biorefineries can be classified according to the raw materials used: starch, sugar, oil or lignocellulose

A biorefinery consists of different biochemical, mechanical or thermochemical processes that are applied one after the other or side by side, each of which must be adapted to the biomass to be processed. There is therefore no one biorefinery, but different ways and possibilities to realize the biorefinery concept. A distinction is made between two basic approaches:

- A bottom-up approach is when existing biomass processing plants are expanded with additional process steps in order to extract valuable substances from existing waste. For example, a fruit juice production plant can add processes for extracting oils or pectins from the peel of the fruit, process the waste into fertilizer or produce biogas from it.

- In contrast, the top-down approach is based on a completely redesigned plant concept that uses coordinated process steps to extract as much valuable material as possible from a particular biomass.

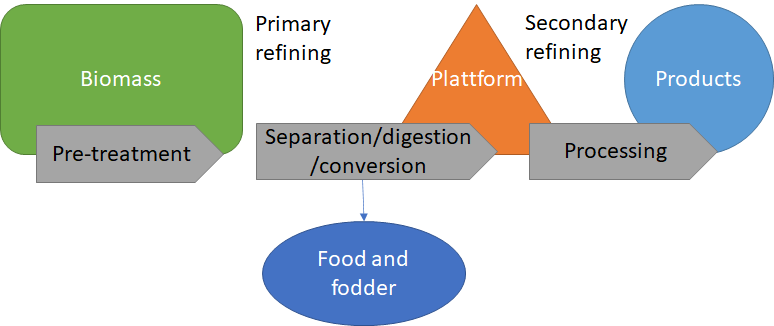

However, some basic process steps can be found in all biorefinery concepts. They are shown schematically in Figure 1 and are briefly described below.

Basic process steps

Mechanical processes are used for pre-treatment (shredding or cleaning of the biomass, removal of impurities).

Mechanical separation, chemical or biological digestion or thermochemical, biochemical conversion into so-called platforms (intermediate products) are the first refining step (primary refining). Processes such as extraction, treatment with strong acids or bases, gasification or fermentation can be used for this purpose. Important platforms are e.g. C5 or C6, sugar, oils, lignin, synthesis gas or biogas.

The platforms produced can then be further processed into marketable chemicals, materials or energy (secondary refining). Food or animal feed is usually already obtained in the primary refining step.