4.2 Applications in the Mobility Sector

| Website: | Hamburg Open Online University |

| Kurs: | Green Hydrogen |

| Buch: | 4.2 Applications in the Mobility Sector |

| Gedruckt von: | Gast |

| Datum: | Mittwoch, 4. Februar 2026, 02:11 |

Beschreibung

Hydrogen-powered vehicles can be used in almost all areas of the transport sector. In this section, you will learn about the possible application areas of hydrogen vehicles based on different modes of transport.

Passenger Cars

Hydrogen-powered fuel cell (FC) electric vehicles are one way of enabling motorised private transport without the emission of greenhouse gases and other air pollutants. Hydrogen-powered passenger cars have been under development for several decades, are today hardly different from cars powered with fossil fuels in terms of functionality and comfort, and can be purchased by private customers.

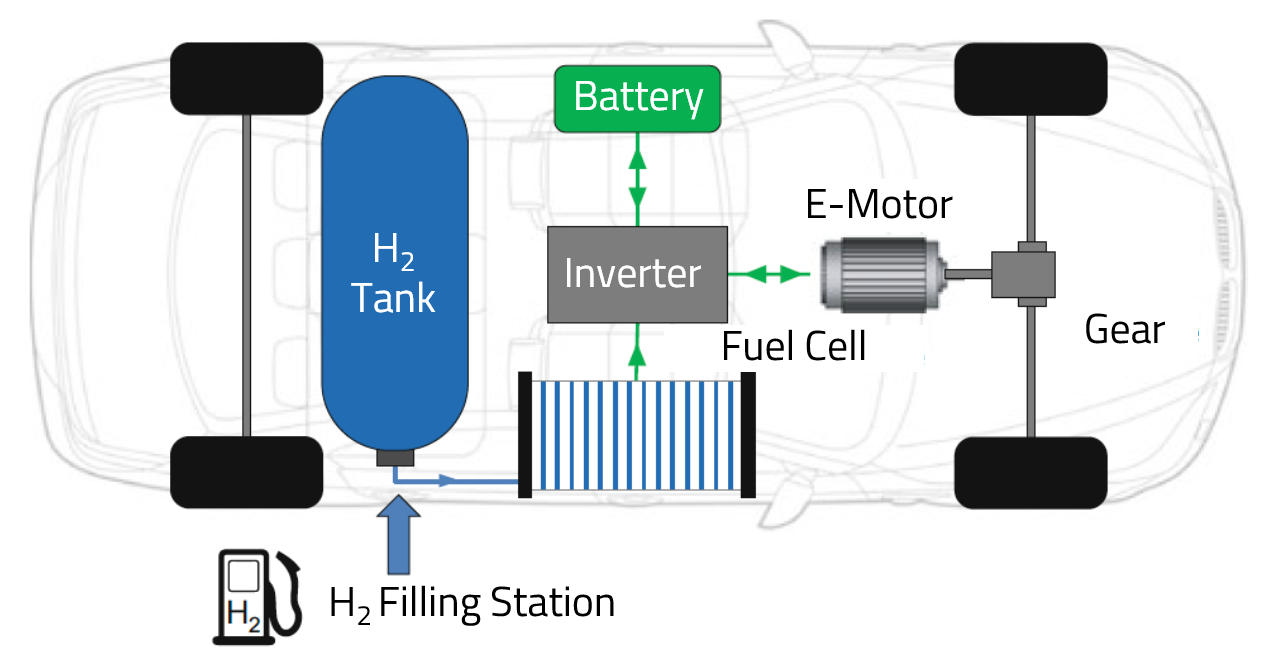

The figure below shows the most important technical components of a car with a FC powertrain. The core element is the FC, in which the hydrogen is converted into electrical energy. Hydrogen-powered vehicles usually use Proton Exchange Membrane Fuel Cells (PEMFC). Special pressure tanks made of plastic reinforced with carbon fibres (so-called Type IV pressure tanks) are used to store the hydrogen. These pressure tanks must be especially stable, as a pressure level of 700 bar has become established in the passenger car sector for on-board hydrogen storage. The electrical energy generated by the FC is used to drive an electric motor, which provides the movement of the vehicle's axle and wheels via a transmission. Since the FC generates direct current, but electric vehicles almost exclusively use alternating current motors, inverters are required. In order to cover load peaks that occur during acceleration, for example, part of the electricity generated in the FC is temporarily stored in a battery.

Although some car manufacturers, especially from Asia, are offering FC passenger cars as series models, their number on the roads has been small up to now. For instance, the number of registered FC cars in Germany at the end of 2021 was only around 1,400. In the USA and some Asian countries, there are significantly more FC cars in use, but even here they play only a minor role in the overall market. A major obstacle to the widespread use of FC passenger cars is not only the high price of the vehicles but also the limited availability of hydrogen filling stations. In Germany there are currently 90 hydrogen filling stations (as of the end of 2021) where FC passenger cars can be refuelled.

Trucks

Unlike in the passenger car sector, where battery-electric vehicles have gained more and more market share in recent years, alternative drives have barely played a role in the truck sector so far. The FC drive is also a possible emission-free option for trucks. In terms of the key technical components of the powertrain, FC trucks differ only marginally from FC passenger cars (see illustration in the paragraph on passenger cars). However, in contrast to FC passenger cars, various concepts are currently being developed for storing hydrogen on board of the truck.

Hydrogen driven trucks have so far only been produced as prototypes for use in pilot projects. Most of these prototypes use gaseous hydrogen compressed to 350 bar. This includes the Hyundai Xcient Fuel Cell - the only hydrogen powered truck that is already in use in larger numbers (e.g., around 50 vehicles in Switzerland since the end of 2020). However, there are also manufacturers which are pursuing the development of FC trucks with 700 bar hydrogen tanks. In recent years, for example, several hydrogen powered waste collection vehicles that use 700 bar technology have been manufactured and put into operation in Germany. Another option, which is being developed in particular by the manufacturer Daimler Trucks, is to refuel the vehicles with liquid hydrogen. Here, the boil-off losses caused by the heat input into the tank system are a challenge. Since especially trucks, which are mainly used in long-distance transport, rarely have long standstill times in daily operation, the boil-off losses may play a subordinate role in such fields of application.

In the truck sector as well, higher ranges can currently be achieved with FC vehicles than with battery-electric alternatives. The Hyundai Xcient Fuel Cell, for example, has a tank capacity of 35 kg hydrogen and therefore achieves ranges of around 400 km. If a storage form with a higher energy density (gaseous at 700 bar or liquefied) is used for the hydrogen, ranges of 1000 km and more are conceivable.

Expert lecture - Hydrogen Trucks

Claudio Schwalfenberg; E-Cap Mobility

Integrating Hydrogen in Commercial Vehicles - Examples, Solutions, Challenges

Busses

FC powertrains can also be used in busses to minimise emissions of greenhouse gases and other air pollutants. Already since the beginning of the 2000s, various public transport operators in Germany began testing FC buses. After some of these pilot tests were stopped, partly due to a lack of availability of suitable vehicles, some public transport operators have integrated a larger number of FC buses into their operations in recent years. By the end of 2021, around 60 FC buses were in operation in Germany. In the light of orders already placed and projects currently being implemented by other operators, it can be assumed that this number will rise significantly in the coming years.

While vehicle availability was a decisive hurdle for the use of FC buses in regular operation a few years ago, there are now several manufacturers (e.g. Van Hool, Solaris) offering series-production vehicles. All FC buses available up to now rely on the 350 bar pressure tanks for storing the hydrogen. The consumption of FC buses ranges from 8.5 to 10.5 kg hydrogen per 100km, depending on the size of the bus and the specific driving profile.

Trains

In contrast to road transport, large parts of rail transport are nowadays already based on drive technologies that can easily be operated in a greenhouse gas-neutral manner. In Germany, for example, around 60% of the entire rail network is electrified, which means that overhead lines are present that can be used to supply trains with electrical energy. For electrified lines, it is therefore sufficient to ensure that the electricity comes from renewable sources to enable climate-neutral train services. Although both, the German government and the rail industry, are striving to continuously increase the share of electrified lines in the coming years, there will still be lines in the future whose electrification does not make sense for technical and, above all, economic reasons.

On such non-electrified lines, trains powered by diesel engines are usually used today. As in road transportation, in rail transportation hydrogen-powered vehicles are one way to replace diesel vehicles with greenhouse gas-neutral alternatives. At the end of 2018, the world's first train powered exclusively by hydrogen was tested in Germany as part of a pilot project. Just three years later, at the end of 2021, hydrogen trains for local passenger transport are already in series production. The pioneer is the french manufacturer Alstom. Local transport operators in several German states (Lower Saxony, Hessen) are currently in the process of creating the necessary conditions for the use of hydrogen-powered train fleets. By the end of 2022, around 40 fuel cell trains are expected to be in regular service.

In terms of the technological design of the powertrain, the hydrogen trains available to date are comparable to the FC vehicles for road transportation. A FC supplied with gaseous hydrogen generates electricity, which in turn drives an electric motor. To compensate peak loads, part of the electrical energy generated by the FC is temporarily stored in a battery. The battery can also be used to store energy that is recovered during braking (recuperation). In Alstom's hydrogen train, the hydrogen tanks and the FC are located on the roof of the train. The batteries, electric motor and required current converters are located on the train's underside.

Expert lecture - Hydrogen Trains

Maximilian von Bose; Alstom Transport Deutschland GmbH

Hydrogen driven train – A way forward?

Aircraft

Today, aviation is responsible for around 2.5 % of anthropogenic CO2 emissions. However, aviation represents a special case, as the share of human-induced warming is not identical to its share of CO2 emissions here. Experts estimate that aviation as a whole is responsible for around 3.5% of global warming. The reason for this is that the emission of aircraft exhaust gases and components contained therein, such as water vapor, nitrogen oxides or soot particles, at high altitudes has an additional warming effect on the climate. Strong global growth in air traffic is forecast over the next few decades. Despite it's currently still relatively small contribution to global warming, a significant reduction of aviations climate impact is required.

The use of hydrogen as a fuel for aircraft is currently the subject of intense debate. Hydrogen aircraft would only affect the climate by emitting water vapor at high altitudes. However, this impact would likely be little compared to the current practice of burning fossil kerosene. The construction of hydrogen aircraft is currently being driven forward by Airbus in particular. The company plans to bring the first hydrogen aircraft in commercial service by 2035.

Current concepts envisage storing the hydrogen on board of the aircraft in liquid form. Other forms of hydrogen storage have either too low volumetric energy densities (cGH2) or too low gravimetric energy densities (LOHC, methanol, ammonia). Even for aircraft fueled with liquid hydrogen, the tank volume will increase three to four times due to the lower volumetric energy density compared to kerosene. For this reason, it is currently assumed that hydrogen aircraft will only be used for short- and medium-haul flights in the foreseeable future. However, synthetic kerosene (e-fuel) appears to be the most suitable option for reducing greenhouse gas emissions from long-haul flights.

Two completely different approaches are currently being considered for the design of the propulsion system of hydrogen-powered aircraft. On the one hand, it would be possible to equip the aircraft with hydrogen turbines so that the necessary thrust could be generated by direct combustion of the hydrogen (“Turbofan” concept). On the other hand, the use of fuel cells is also conceivable. In this case, the hydrogen would first be converted into electrical energy. The electrical energy would drive several propellers via an electric motor, which in turn would provide the thrust (“Turbopro” concept). Which of the two drive concepts will be used in the future, or if even both variants will be realized, is unclear as of today.