6. Bioplastics

| Website: | Hamburg Open Online University |

| Kurs: | Process engineering for the bioeconomy |

| Buch: | 6. Bioplastics |

| Gedruckt von: | Gast |

| Datum: | Donnerstag, 29. Januar 2026, 23:17 |

Beschreibung

A book about the different types of bioplastics.

6. Bioplastics

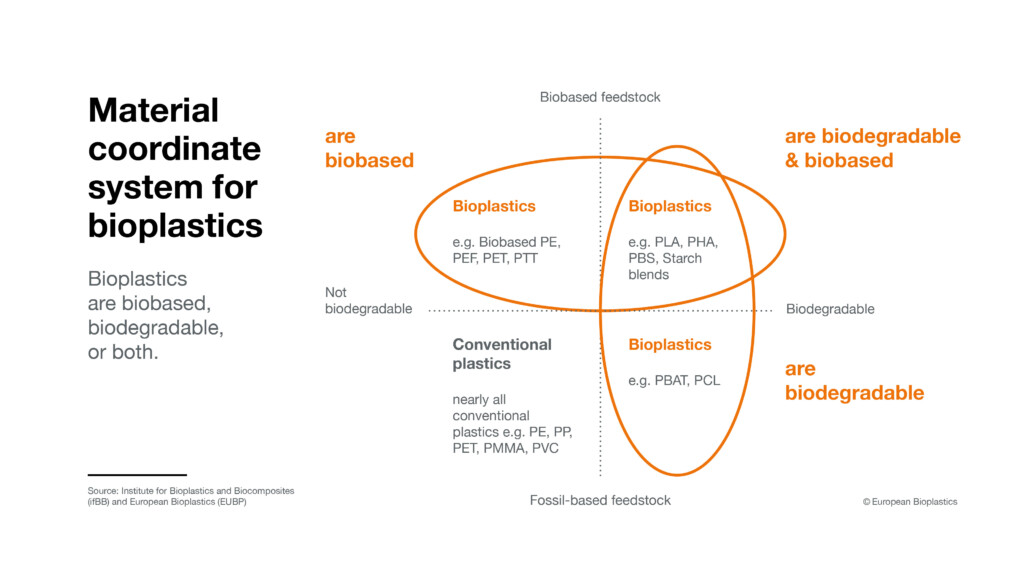

Bioplastics are plastics that are either biobased or biodegradable. The latter category can therefore also include petroleum-based plastics. There are sometimes major differences in the biodegradability of materials. The speed of degradation and the conditions required for this are also decisive. Plastics are labeled as compostable if they can be degraded without residue within a certain period of time in an industrial composting plant or in domestic compost. Bio-based plastics are made from starch, cellulose or even proteins, chitin or lignin.

6.1 Biodegradable, biobased plastics

Polylactid Acid (PLA)

- lactic acid is obtained from starch or sugar by fermentation using lactic acid bacteria

- Polylactide is synthesized from the lactic acid

- available in large quantities,

- important plastic for the packaging industry

- Prices for PLA have fallen in recent years (approx. 2 EUR/kg)

- PLA is currently being produced in large quantities in the USA, the Netherlands and Germany/China

Polyhydroxyalkanoate (PHA)

- PHA is produced by biosynthesis of various algae and bacteria as an energy storage molecule

- For this, bacterial cultures must be fed with glucose or other carbohydrate-rich nutrients

- Polyhydroxybutyrate (PHB) are polyhydroxyvalerate (PHV)

- and polyhydroxybutyrate-co-valerate (PHBV)

- not soluble in water, UV-resistant

- not resistant to acids and bases

- non-toxic and biocompatible, biodegradable

- relatively expensive (3-15 EUR/kg)

- are used for beverage packaging, disposable items, agricultural films or bin liners

Starch-Blends

- the most common biodegradable plastic

- Plastics made from starch blends consist of two phases.

- Hydrophobic polymer (mostly degradable polyester) and hydrophilic thermoplastic starch (25-70%)

- both phases are combined during a melting process to form a waterproof starch plastic

- Industrial production in Italy, Germany, Netherlands, Austria

Polyester from cellulose

- esters and ethers from cellulose, which is obtained from wood, are used = cellulose acetate

- in principle, it is viscose in film form (see viscose production)

- as technical acetic acid and plasticizers are used in production, the product is not 100% bio-based

- Film made from cellulose hydrate, also known as cellophane

- In principle, the material is biodegradable, but coatings delay degradation

- Used as packaging, coatings, cigarette filters

- Industrial production in UK/USA, Japan, Germany, Austria

6.2 Biodegradable, fossil-based plastics

Polybutylene succinate (PBS)

- belongs to the polyesters,

- PBS is synthesized by polycondensation of the two monomers succinic acid and 1,4-butanediol

- can be obtained from fossil raw materials, but also from glucose

- is also biodegradable in water

- can be easily processed (printing, welding, production of film)

- Packaging, disposable cutlery, mulch films, composite materials

Polybutylene adipate terephthalate (PBAT)

- Copolymer/ copolyester

- based on 1,4 butanediol, adipic acid and terephthalic acid

- mostly produced from fossil raw materials

- Similar properties to polyethylene

- good elasticity, thermal resistance

- Biodegradable, compostable in industrial plants

- Production of films for packaging, garbage bags, shopping bags or mulch films

- can also be used with starch to make starch blends

6.3 Non-degradable, bio-based plastics

Polyethylene (PE)

- widely used plastic (petroleum-based: 30% of the plastic produced worldwide)

- Soft, flexible, translucent, odorless

- Production of packaging, films, insulating material, bottles

- resistant to oils, acids, bases, bio-based PE lower barrier properties

- flammable, not weather and UV resistant,

- relatively good recyclability

- Production based on ethanol from sugar cane in Brazil

Polypropylene (PP)

- widely used plastic (petroleum-based: 24% of the plastic produced worldwide)

- Relatively hard, strong, high thermal stability, acid-resistant

- Production of drainpipes, car parts, housings for electrical appliances, garden furniture, packaging, FFP2

- masks (made from PP fibers)

- Easily recyclable, but not biodegradable

- breaks down into microplastic particles under UV radiation

- Bio-based production from vegetable oils without significant change in properties

- Price of the bio-based variant 50 to 100 % higher than petroleum-based PP

- Commercial production based on hydrogenated vegetable oils currently relatively low (2 plants in Germany and Belgium)

Polyamide (PA)

- Plastic made from monomers that are linked via amide bonds to form polymers

- high strength, high toughness, abrasion-resistant, good chemical resistance to organic solvents, not acid-resistant

- Known as Perlon, Dederon or nylon

- Manufacture of clothing, technical fabrics, strings for musical instruments, household items, vehicle parts, insulators

- Recyclable, but not biodegradable

- Bio-based production of monomers from vegetable oils, without significantly changing the properties of the PA

- commercial production based on castor oil currently relatively low (2 plants in Germany and France)

Polytrimethylene terephthalate (PTT)

- belongs to the polyesters

- elastic, dimensionally stable, soft

- Used as fibers for carpets or textiles, technical plastics

- The starting material is 1,3 propanediol

- 1,3 propanediol can also be produced biochemically

- not biodegradable

- Production capacities for bio-based 1,3 propanediol mainly in the USA and China

Rubber

Rubber is a completely natural biopolymer that has been used by humans for a long time. It is obtained from the latex of the rubber tree, which is found in tropical regions in South America, Africa and Asia. Rubber is produced when sulphur is added and heated (vulcanization). Charles Goodyear developed this process in 1839 and tires, seals, gloves, shoe soles and mattresses are still made from rubber today. Unlike the raw material rubber, the product rubber is not biodegradable or compostable.

At the beginning of the 20th century, the history of rubber production was also closely linked to colonization in Africa and South America, where the expected profits from rubber marketing led to exploitation and violence against the original population.