Maritime Transport System

| Website: | Hamburg Open Online University |

| Kurs: | MoGoLo - Mobility of Goods and Logistics Systems |

| Buch: | Maritime Transport System |

| Gedruckt von: | Gast |

| Datum: | Dienstag, 3. März 2026, 05:51 |

Beschreibung

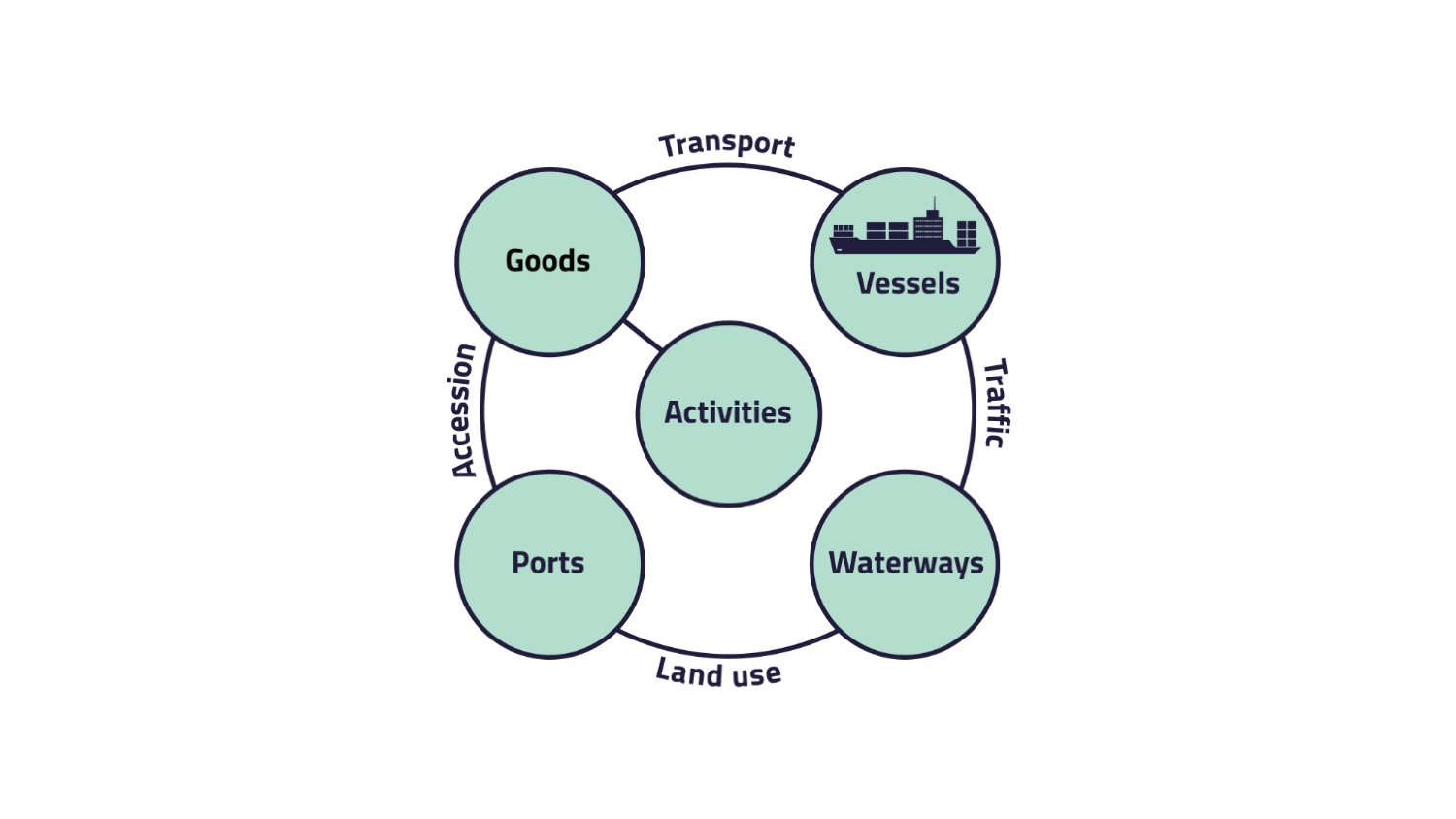

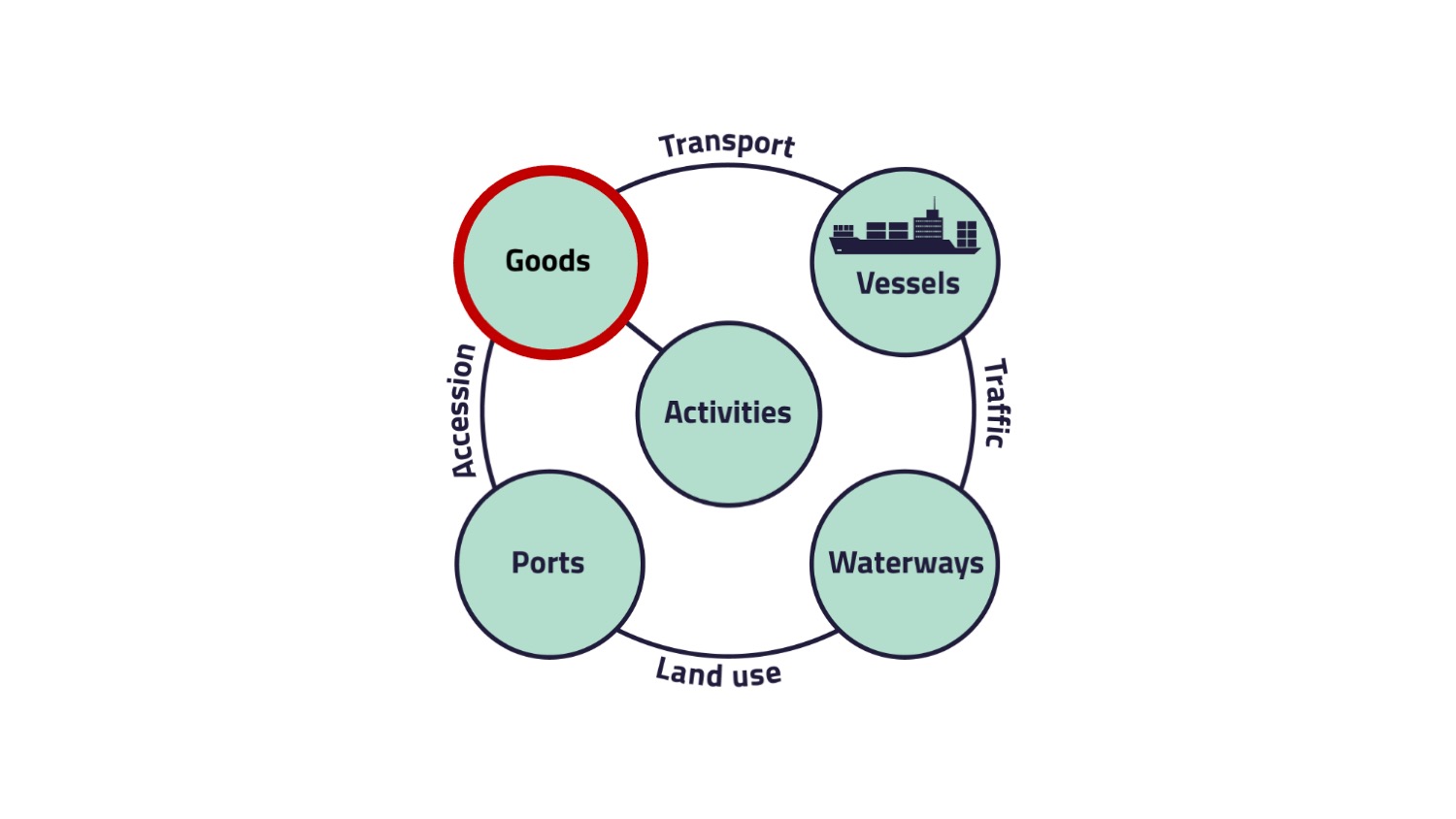

In this section you will learn more about maritime transport and its

elements: activities, goods, vessels, waterways and ports. As in the

last sections, this section follows the structure of the conceptual system model of transport and traffic.

1. Introduction

In this section, you will learn more about the maritime transport system. You will get to know the activities that drive this system and the goods that are transported on waterways. You will then be introduced to the vessels used for transportation. In addition, the infrastructure of the waterways and its port facilities will be explained. Finally, the advantages and disadvantages of maritime transport will be highlighted.

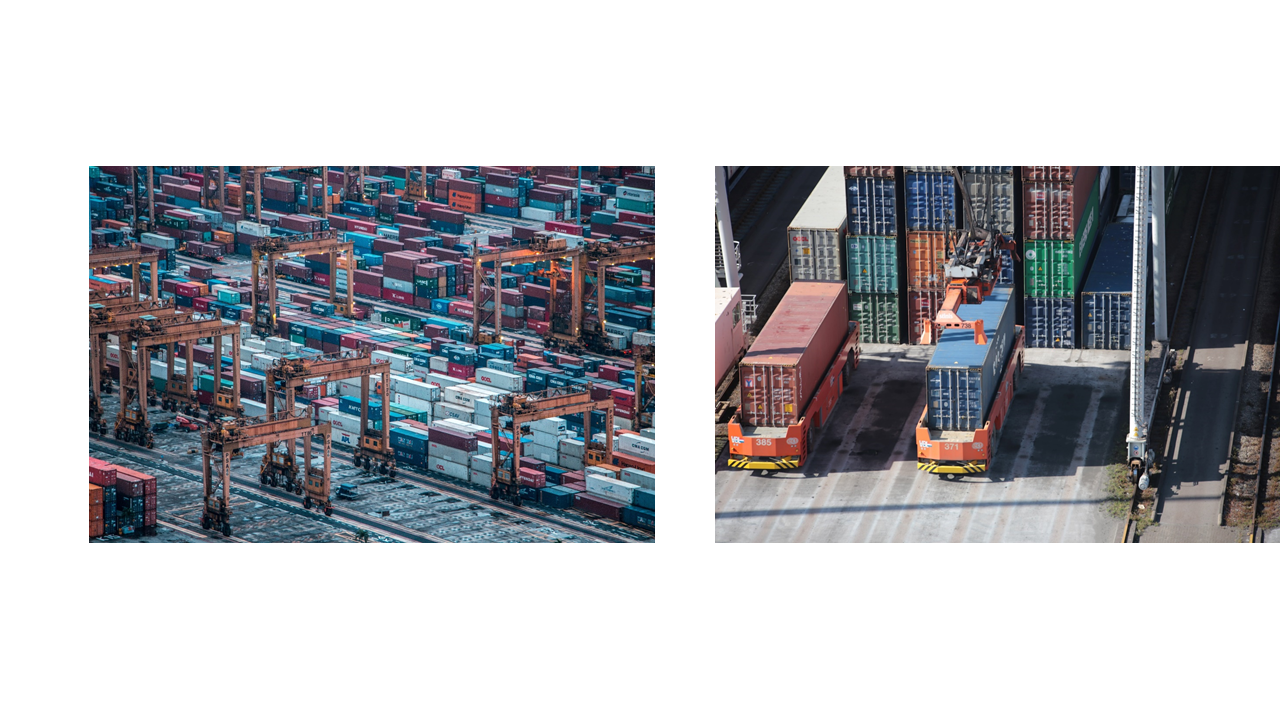

Maritime transport is often responsible for the main carriage of goods and therefore for the long distance transport and is a part of a multimodal transport chain.

Multimodal transport describes the carriage of goods by two or more modes of transport.

Is the movement of goods in one and the same loading unit, e.g. container, or a vehicle by successive modes of transport without handling of the goods themselves when changing modes, it is called intermodal transport.

Combined transport is an intermodal transport with the majority of the journey in Europe being made by rail, inland waterways or sea and any initial and/or final legs carried out by road are as short as possible.

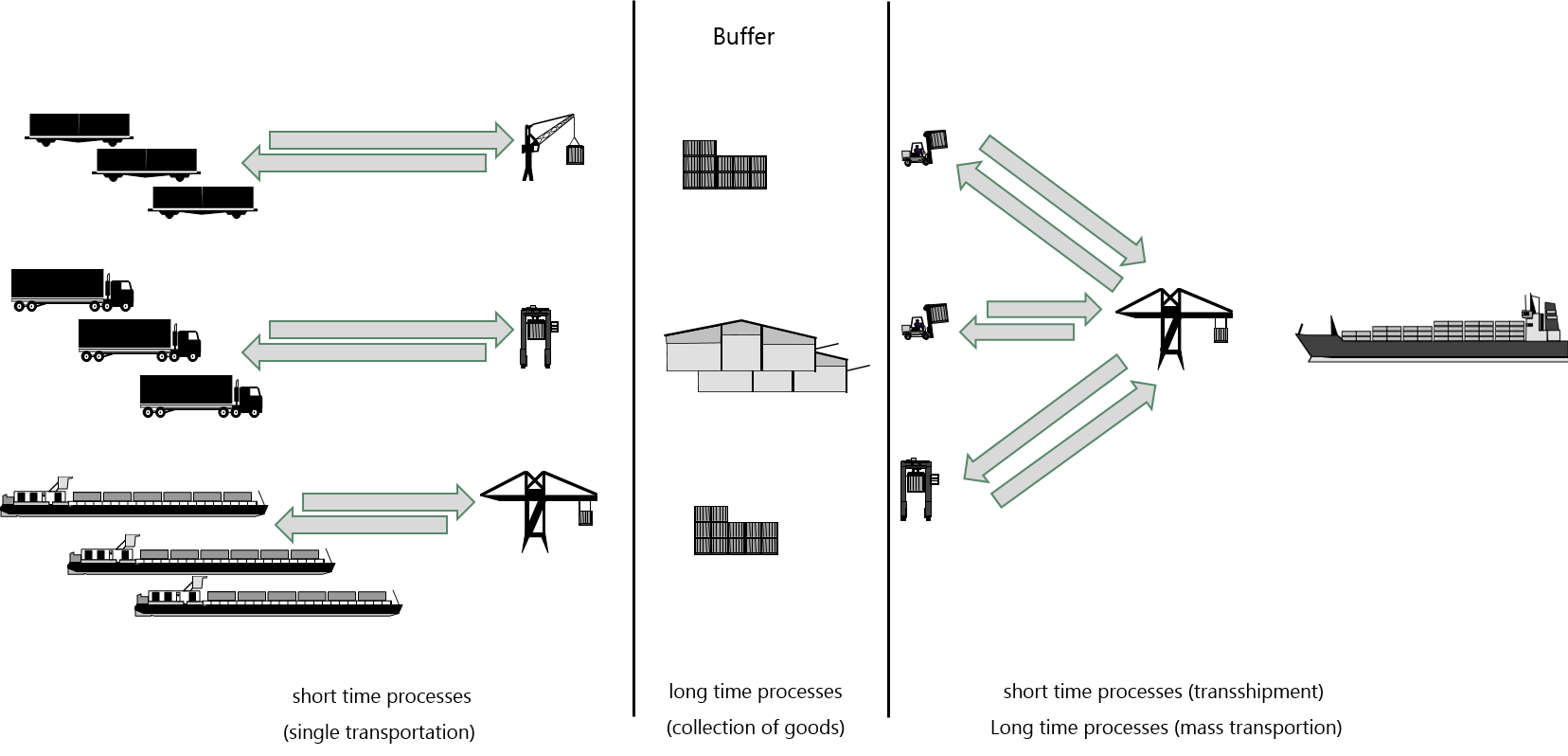

The figure "Maritime transport" shows the leg of the maritime transport between two ports with their connections to the hinterlands.

On the next page, the activities of the maritime transport system are presented to you.

Flämig, H., Sjöstedt, L., Hertel, C. (2002): Multimodal Transport: An Integrated Element for Last-Mile-Solutions? Proceedings, part 1; International Congress on Freight Transport Automation and Multimodality: Organisational and Technological Innovations. Delft, 23 & 24 May 2002. (modification of Sjöstedt 1996)

Schönknecht, Axel (2009): Maritime Containerlogistik. Leistungsvergleich von Containerschiffen in intermodalen Transportketten. Berlin, Heidelberg: Springer Berlin Heidelberg (VDI-Buch).

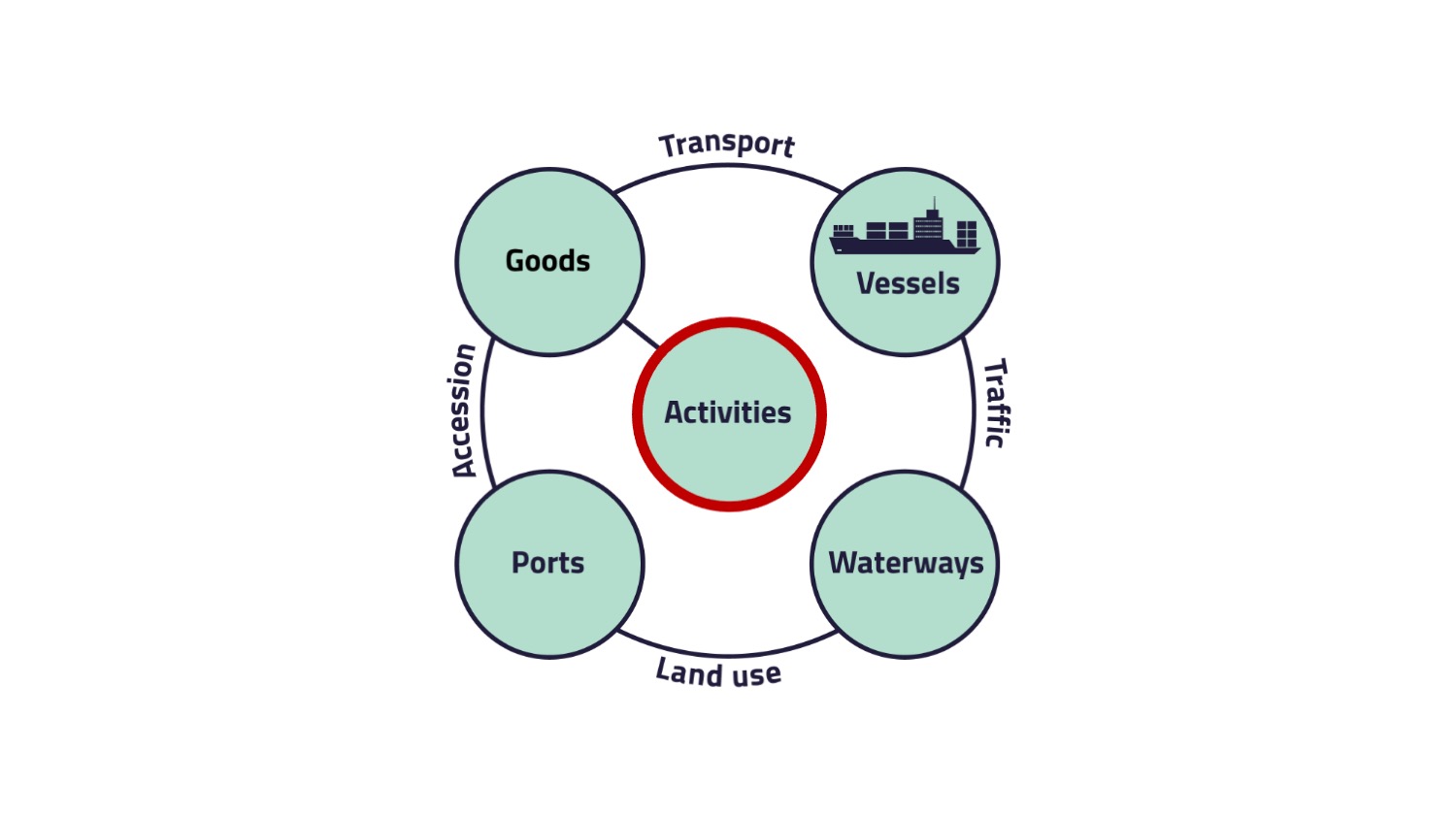

2. Activities

On this page, the element "Activities" of the conceptual system model of transport and traffic will be presented to you.

Literature

Flämig, H., Sjöstedt, L., Hertel, C. (2002): Multimodal Transport: An Integrated Element for Last-Mile-Solutions? Proceedings, part 1; International Congress on Freight Transport Automation and Multimodality: Organisational and Technological Innovations. Delft, 23 & 24 May 2002. (modification of Sjöstedt 1996)

3. Goods

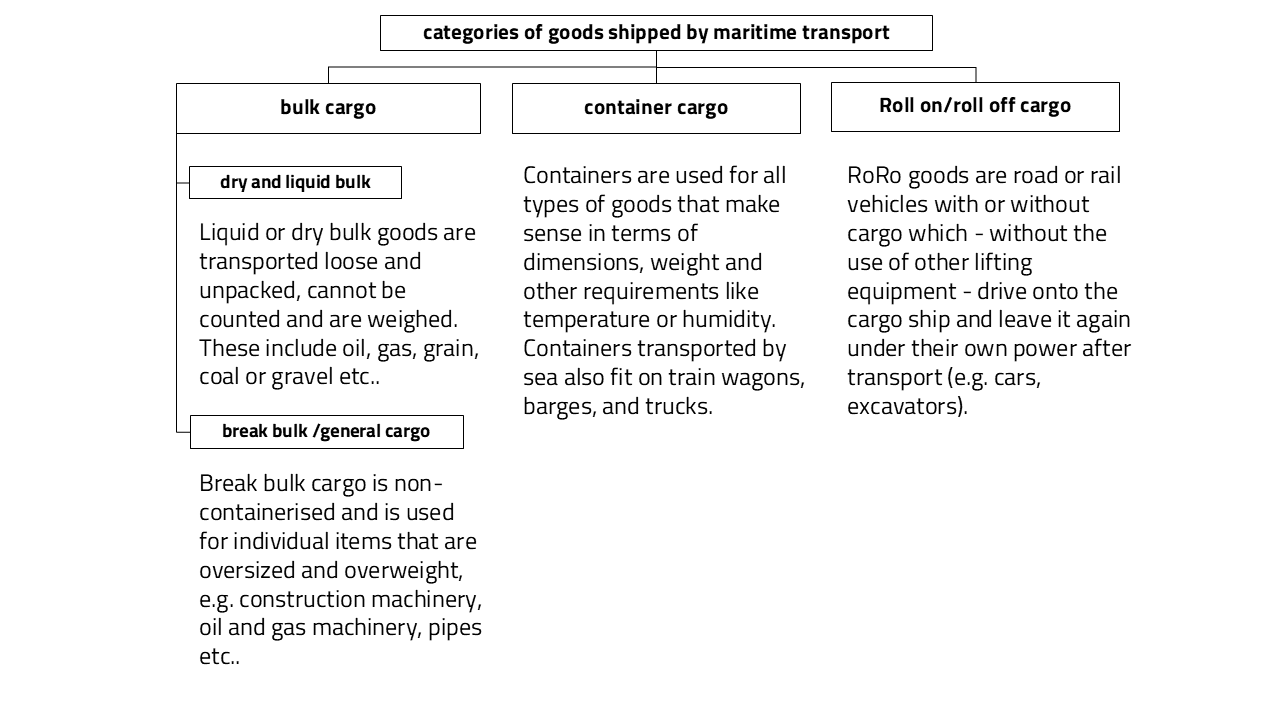

The next element of the conceptual system model deals with the types of goods, being typically transported with the presented mode of transport. We will show you on this page, what types of goods are typically transported by maritime transport.

The goods can be divided into three categories:

- bulk cargo,

- container cargo and

- roll on / roll off cargo.

For the transport of goods, the figure "Load carrying devices" shows, what different kinds of loading devices can be used. Those load carrying devices can be differentiated in the categories supporting, enclosing and locking.

For those ground traffic containers, the standard measure is in feet (1 foot = 0,3048 m). An ISO-container is 20 or 40 feet long.

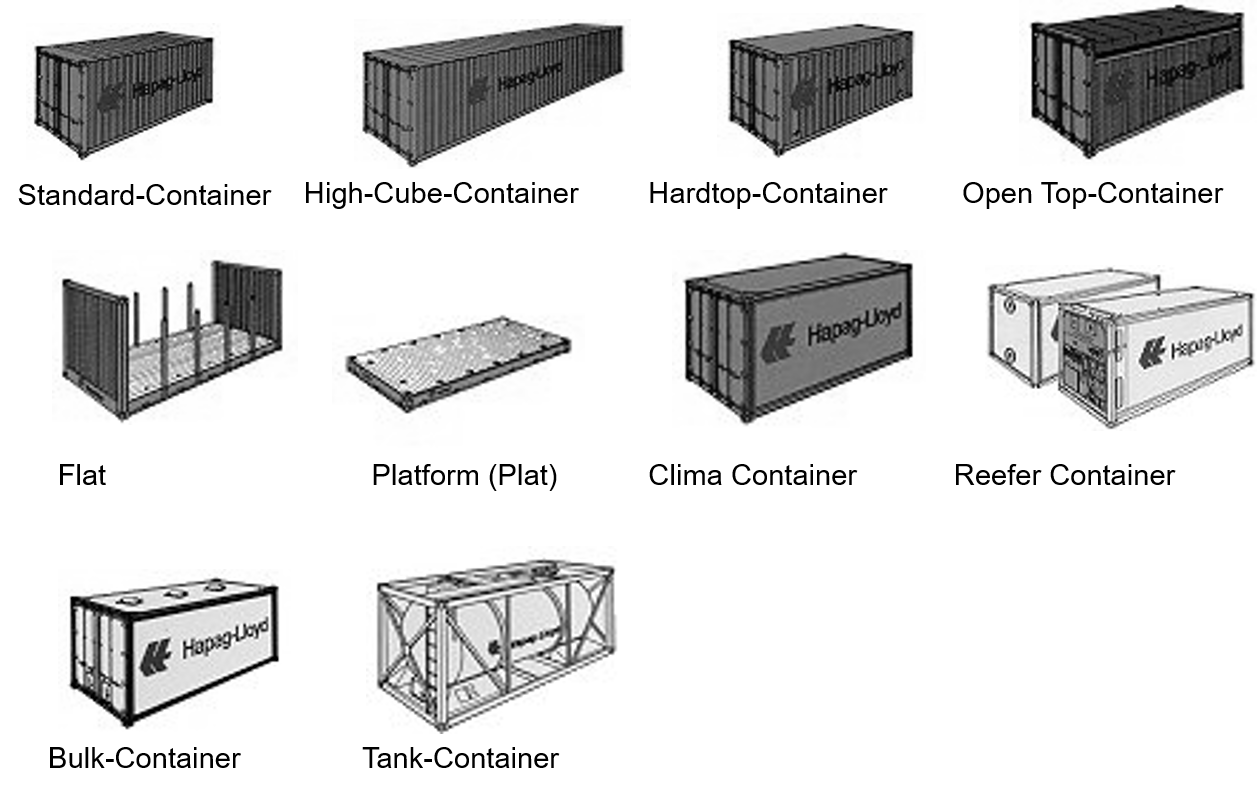

The following figure "Container equipment" shows different kind of ground traffic containers. The kind of goods being transported influences the decision about the container type being used.

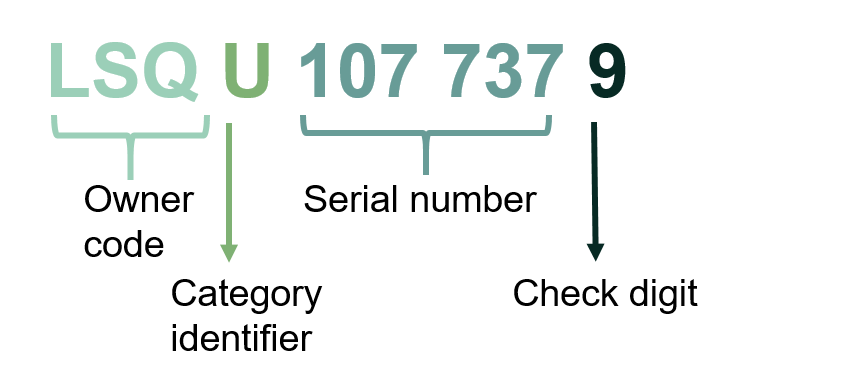

This container number consists of 11 characters.

- The first three letters are showing the owner of the container.

- The fourth letter shows the product category, the U stands for container.

- The first six numbers are the serial number of the container.

- The last number is the check digit.

Containers can be provided by different stakeholders:

- shipping company provides container

- forwarding company provides rented container or

- shippers own container (SOC)

In Maritime Transport, a differentiation is made between Full Container Load (FCL) and Less than Container Load (LCL).

FCL

- volume of freight has sufficient volume for a complete container load

- shipper organizes loading and securing

- containerized transport at least to the port of destination

- volume of freight has insufficient volume for a complete container load

- transport of container part load to Container freight station (CFS)

- consolidation and transport to the port of destination

- LCL service surcharges due to additional handling processes

The ISO-container is a good example for standardization. Advantages of standardization are for example, space utilization, easy handling and safety.

A transport chain with containers has various value-adding roles:

- uniformly unit load (standard size, reusable, stackable)

- high velocity of transhipment process

- internationalization

- reduction of packaging

- suitable for all means of transport

- suitable for inland and overseas transport

If you are interested in the influence of containers on logistics strategies, transport systems and transport chains, feel free to check it here.

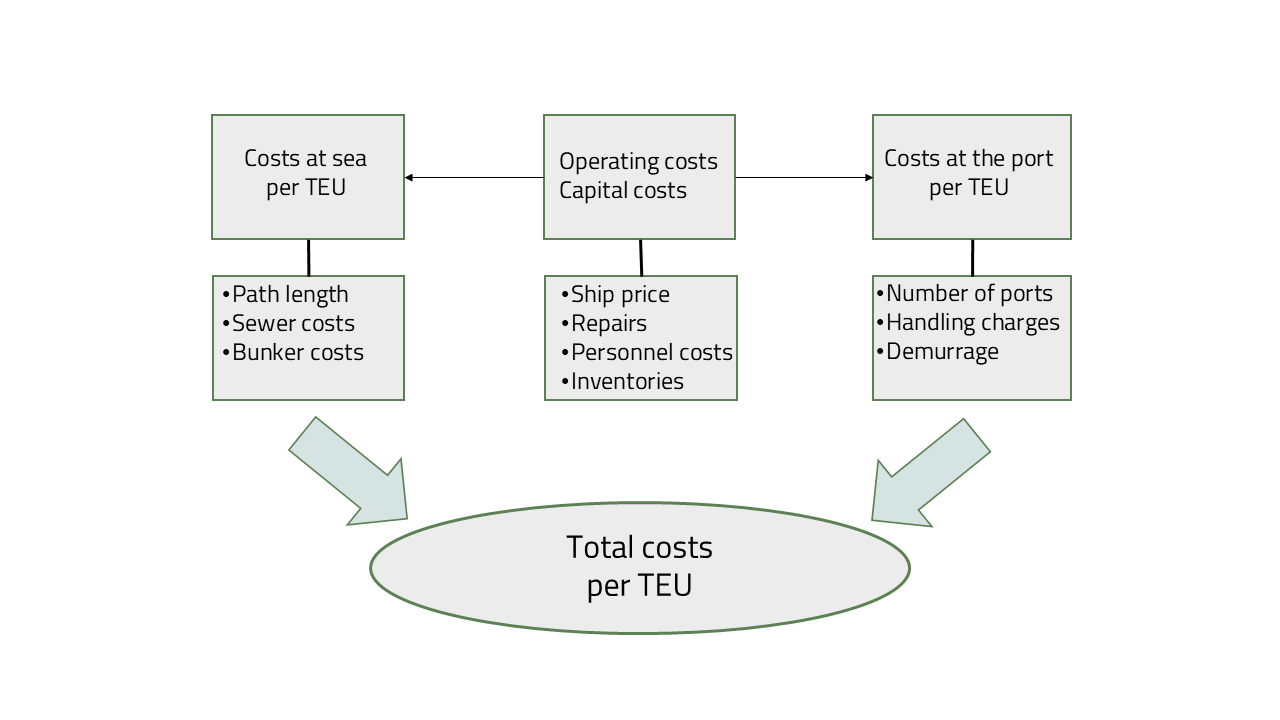

The total costs per TEU are shown in the figure "Total costs per TEU" and are composed of three different elements costs at sea, operating costs and capital costs and costs at the ports.

Transport

Liner service operators

- operational business

- maintenance/survey/storage/supply of vessels

- accounting and market intelligence/viewing

- retail and other business

- Handling of door-to-door transport by carrier on behalf of client.

- Approximately 2/3 of the worldwide transport.

- Independent handling of pre- and subsequent-leg by shipper/recipient or by forwarder on behalf of shipper.

- Normally only pier-to-pier transport.

- The shippers/consignees themselves remain in control and subcontract all involved transport operators. If it's necessary also pier-to-door or door-to-pier transport is possible.

Carrier’s and Merchant’s haulage are shown in the next figure "Carrier's and merchant's haulage".

Door-to-Door Transport (FCL):

Door-to-Pier Transport:

Pier-to-Door Transport:

Pier-to-Pier Transport:

Partners in transportation business

For organizing and operating maritime transport, different stakeholders are necessary.

Some examples for the partners are:

- forwarders

- authorities

- export companies

- import companies

- hauliers

- stevedore companies

- tally

- agents

Biebig, P.; Althof, W.; Wagener, N. (2008): Seeverkehrswirtschaft: De Gruyter Oldenbourg.

Bloech, J. & Ihde, G. (1997): Vahlens großes Logistiklexikon. München: Beck.

Branch, A. (Hg.) (1996): Elements of Shipping. London.

DSV (2023): Break Bulk. URL: https://www.dsv.com/de-de/unsere-loesungen/transportarten/seefracht/breakbulk (last access: 08.05.2023)

Heidenblut V., Hompel M. (2011): Taschenlexikon Logistik

International Forwarding Association (2019): Types of Cargo Shipped by Sea Freight Transport. URL: https://ifa-forwarding.net/blog/sea-freight-in-europe/types-of-cargo-shipped-by-sea-freight-transport/ (last access: 08.05.2023)

ISO (1999): ISO 830:1999-09. Beuth-Verlag, Berlin, 1999.

ISO (2013): DIN EN ISO 6346/A3:2013-03, ISO-Container-Kodierung, Identifizierung und Kennzeichnung. Beuth-Verlag, Berlin, 2013.

Hapag Lloyd (2016): Container Specification. URL: https://www.hapag-lloyd.com/content/dam/website/downloads/press_and_media/publications/15211_Container_Specification_engl_Gesamt_web.pdf (last access: 30.03.2022).

Flämig, H., Sjöstedt, L., Hertel, C. (2002): Multimodal Transport: An Integrated Element for Last-Mile-Solutions? Proceedings, part 1; International Congress on Freight Transport Automation and Multimodality: Organisational and Technological Innovations. Delft, 23 & 24 May 2002. (modification of Sjöstedt 1996)

Grig, R. (2012): Governance-Strukturen in der maritimen Transportkette. Agentenbasierte Modellierung des Akteursverhaltens im Extended Gate. Zugl.: Berlin, Techn. Univ., Diss., 2012. Berlin: Univ.-Verl. der Techn. Univ. Berlin (Schriftenreihe Logistik der Technischen Universität Berlin, 19).

Ihde, G. (2001): Transport, Verkehr, Logistik. Gesamtwirtschaftliche Aspekte und einzelwirtschaftliche Handhabung. 3., völlig überarb. und erw. Aufl. München: Vahlen (Vahlens Handbücher der Wirtschafts- und Sozialwissenschaften).

Jünemann, R. (1989): Materialfluss und Logistik. Systemtechnische Grundlagen mit Praxisbeispielen. Berlin, Heidelberg, New York, London, Paris, Tokyo, Hong Kong: Springer (Logistik in Industrie, Handel und Dienstleistungen).

Pawlik, T. (1999): Seeverkehrswirtschaft. Internationale Containerlinienschifffahrt Eine betriebswirtschaftliche Einführung. Wiesbaden: Gabler Verlag (Springer eBook Collection Business and Economics).

Schönknecht, A. (2009): Maritime Containerlogistik. Leistungsvergleich von Containerschiffen in intermodalen Transportketten. Berlin, Heidelberg: Springer Berlin Heidelberg (VDI-Buch).

Veenstra, A. (2005): Empty container reposition: the port of Rotterdam case. In: Simme Douwe P. Flapper, Jo A.E.E. van Nunen und Luk N. van Wassenhove (Hg.): Managing Closed-Loop Supply Chains. Berlin, Heidelberg: Springer Berlin Heidelberg, S. 65–76.

Voth, M. (Hg.) (2001): Speditionsbetriebslehre. Herne.

3.1. Quiz - Container sizes

4. Vessels

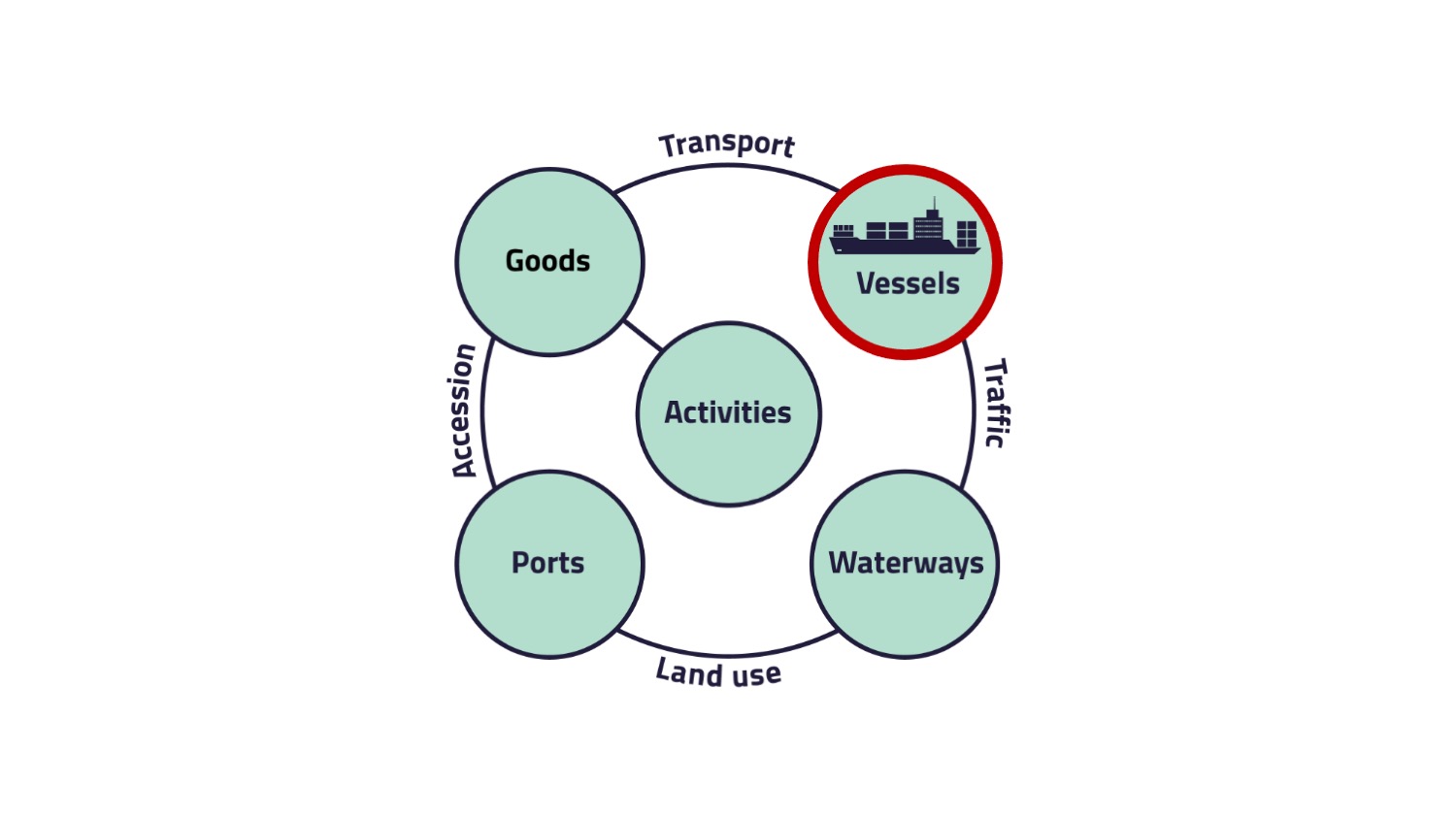

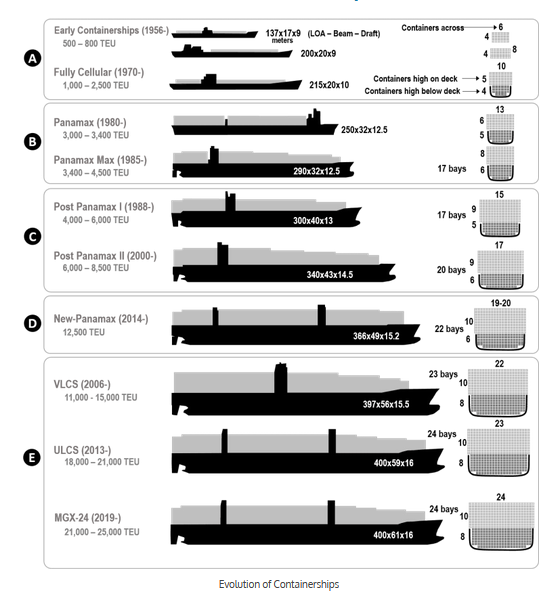

In the maritime transport system model, the movables are called "Vessels". These vessels are presented to you on this page.

The figure "Vessel types" shows a classification of different vessel types, that are used in maritime transport. Some of the vessels are presented to you in detail below.

1. Panamax Class

- capacity: < 4.500 TEU

- length: 250 m

- width: < 32,20 m

- depth: 12,5 m

2. Post Panamax Class

- capacity: > 4.000 TEU < 8.500 TEU

- length: 300 m

- width: > 32,20 m < 43 m

- depth: 13 m

Since the Expansion of the Panama Canal, ships up to a length of 366 m, a width of 49 m and a depth of 15,2 m can pass the canal. Those ships are called Neo Panamax Class.

3. Neo Panamax Class

- capacity: < 12.500 TEU

- length: 366 m

- width: < 49 m

- depth: 15,2 m

- capacity: < 15.000 TEU

- length: 397 m

- width: < 56 m

- depth: 15,5 m

- capacity: < 21.000 TEU

- length: 400 m

- width: < 59 m

- depth: 16 m

- capacity: > 21.000 TEU

- length: 400 m

- width: < 61 m

- depth: 16 m

Advantages of growth (Economies of Scale)

Cost of capital

- required engine power increases by 0,7 with more power

- less material needed for the surface of bigger spaces

- crew size independent from the size of the vessel (for a capacity bigger than 2.000 TEU)

- no correlation between administrative costs and vessel size

Bunker costs

- bunker costs are related to the engine power, thus relative costs are declining with increasing size.

Freight acquisition

- lower freight rates through economies of scale lead to strong market growth

Lay days in harbour

- bigger ships have to unload more containers at one location

- many ports are not equipped to handle those amounts efficiently

- limitations to the maximum draught

- efficiency of hinterland logistics

- liner services consist of 5-6 ships

- financing can become quite problematic, as this means investments of up to one billion € per service

Feeder costs

- increasing costs through additional handling operations

- longer travel times for the feeders through additional handling operations

Cost of insurance

The total costs of costs in port and costs at sea are presented in the figure "Relationship between costs and ship size".

Ro-Ro Vessels

Ro-Ro Vessels (Roll-on Roll-off) vessels are used for the transport of movable goods. Those goods like cars, trucks or trains can roll on and roll off the vessels on their own. With the help of tractors or swap bodies standardized loading units can be transported with this vessel type as well. Those ships have decks with adaptable heights, allowing a flexible usage of the loading space. The vessels have side, bow or stern hatches so that the movables can be driven on board via ramps.

Bulk Carrier

1. Handy Size Bulk Carrier

- capacity: up to 40.000 dwt (Deadweight tonnage)

- capacity: up to 45.000 dwt

3. Panamax Bulk Carrier

- capacity: up to 99.999 dwt

- width: < 32,20 m

4. Capesize Bulk Carrier

- capacity: over 100.000 dwt

1. Handysize Tanker

- capacity: 50.000 dwt

2. Panamax Tanker

- capacity: 65.000 – 80.000 dwt

3. Suezmax Tanker

- capacity: 120.000 - 180.000 dwt

4. Very Large Crude Carrier (VLCC)

- capacity: 200.000 – 320.000 dwt

5. Ultra Large Crude Carrier (ULCC)

- capacity: >320.000 dwt

Traffic

In order to save fuel and reduce emissions in maritime traffic, vessels are reducing their speed. As a rule of thumb, a ship’s engine load is related to the third power of its speed. Numerically, a 10% speed reduction results in a 27% engine load reduction.

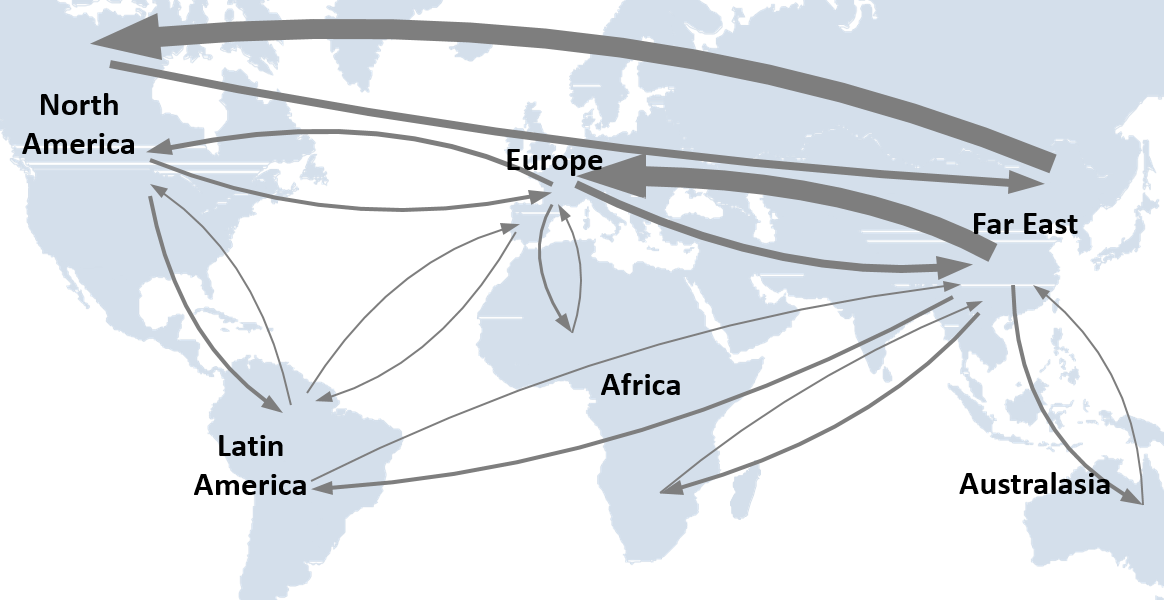

The main maritime traffic routes and dimension of the traffic volume, which is visualized by the arrow thickness, are shown in the figure "Maritime traffic routes".

- port management system,

- systems dedicated to port security,

- support systems and management of pilotage,

- load management systems and overall property,

- docking planning,

- systems for collecting port taxes,

- quarantine control,

- customs control, and

- support for Coast Guard operations such as repression of illicit acts on ships, smuggling, drug trafficking, etc.

For maritime traffic it is necessary to use the waterways, which will be presented to you on the next page.

Literature

Faber, J.; Nelissen, D.; Hon, G.; Wang, H.; Tsimplis, M. (Hg.) (2012): Regulated Slow Steaming in Maritime Transport. An Assessment of Options, Costs and Benefits.

Flämig, H., Sjöstedt, L., Hertel, C. (2002): Multimodal Transport: An Integrated Element for Last-Mile-Solutions? Proceedings, part 1; International Congress on Freight Transport Automation and Multimodality: Organisational and Technological Innovations. Delft, 23 & 24 May 2002. (modification of Sjöstedt 1996)

Jansson, J. O.; Shneerson, D. (1987): Liner Shipping Economics. Dordrecht: Springer Netherlands.

Marvest GmbH (2021): Massengutfrachter. URL: https://www.marvest.de/magazin/schiffe/massengutfrachter/ (last access: 30.03.2022).

Rodrigue, J. (2020): The geography of transport systems. Fifth edition. London, New York: Routledge.

Schönknecht, A. (2009): Maritime Containerlogistik. Leistungsvergleich von Containerschiffen in intermodalen Transportketten. Berlin, Heidelberg: Springer Berlin Heidelberg (VDI-Buch).

Shelter Training Academy (2021): Vessel Traffic Management Information System (VTMIS). URL: https://sheltermar.com/vts/vtmis/ (last access: 30.03.2022).

Transway Internationale Spedition GmbH (2021): Informationen zu Schwergutfrachter. URL: https://spedition-seefracht.de/de/lexikon/schwergutfrachter (last access: 30.03.2022).

5. Waterways

The next element of the conceptual system model is called infrastructure. In case of the maritime transport system, the infrastructure is called "Waterways".

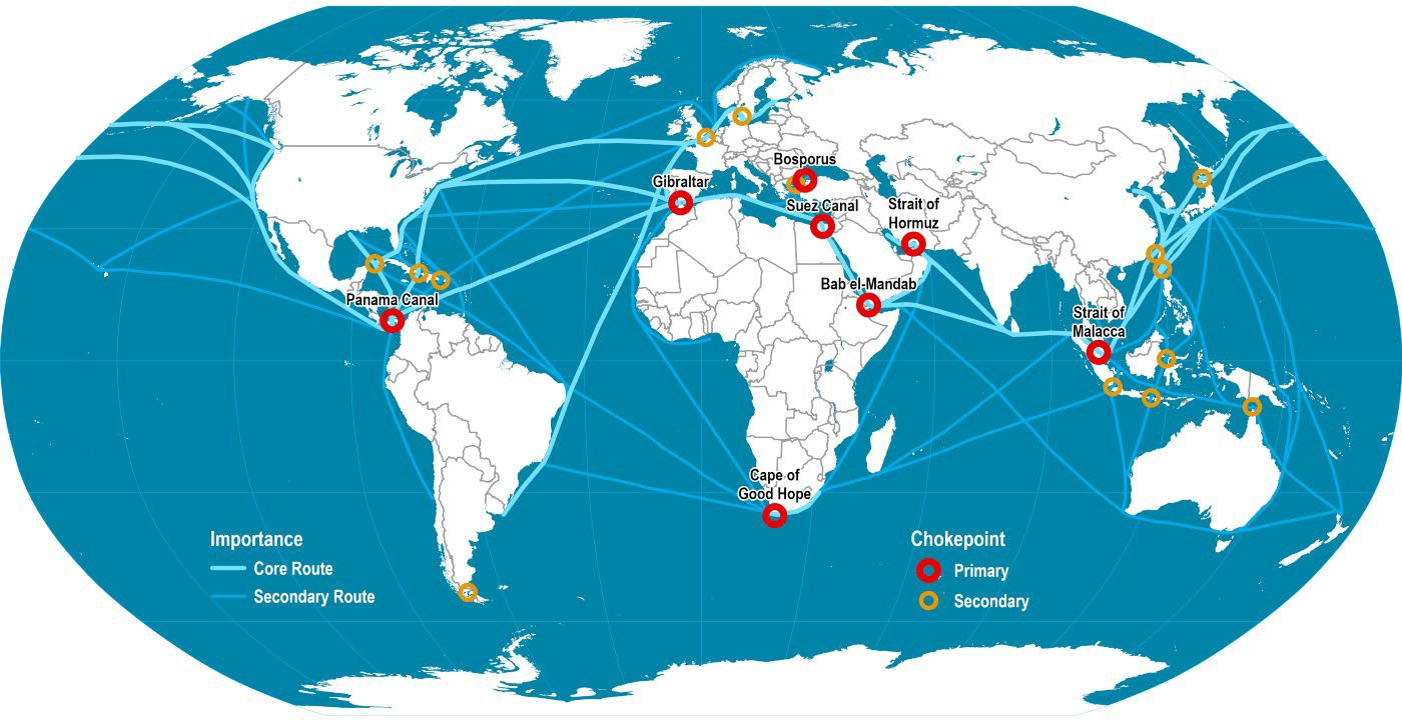

Waterways are the infrastructure, the vessels are using to travel from Port A to Port B. There are approximately 200 narrow bodies of water connecting two larger bodies of water (straits) or canals around the world. A handful of them are known as chokepoints, which means, this waterway could be blocked and stop the maritime transport by accidents or political reasons.

- Panama Canal

- Suez Canal

- Cape of Good Hope

- Gibraltar

- Bosporus

- Strait of Hormuz

- Bab el-Mandab

- Strait of Malacca

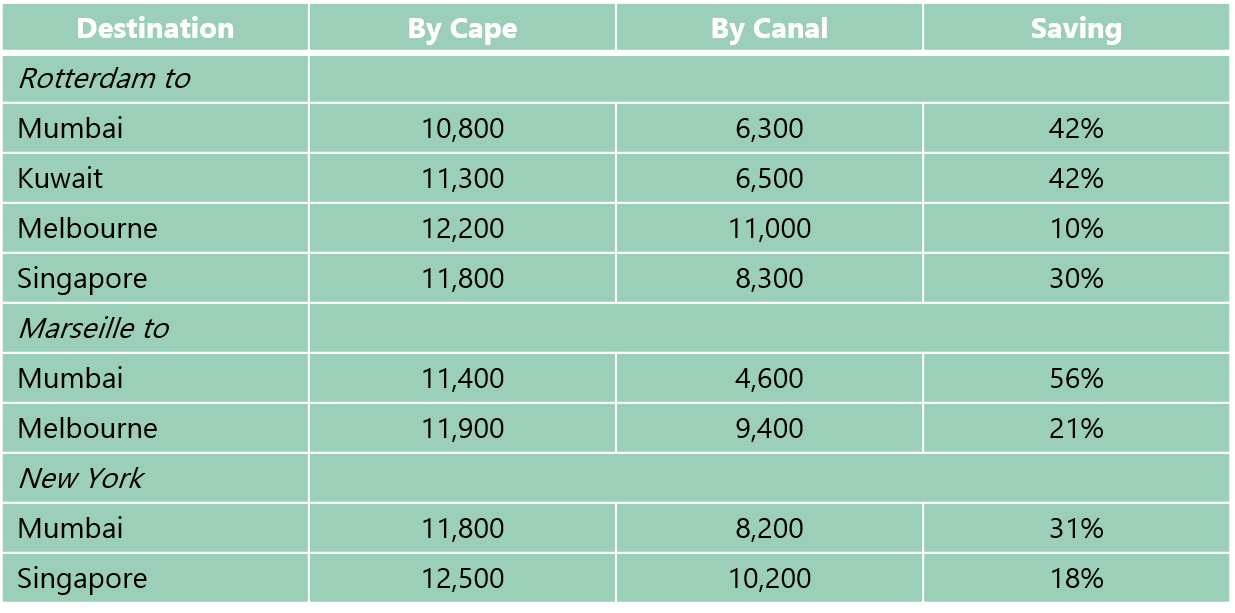

Suez Canal

The following table shows the saved distance by using the Suez Canal instead of the route around the Cape of Good Hope.

The relation between waterways and ports is called land use.

Land use

Panama Canal Authority (2022): How does it work. URL: https://pancanal.com/en/history-of-the-panama-canal/#howdoesitwork (last access: 30.03.2022).

Rodrigue, J. (2020): The geography of transport systems. Fifth edition. London, New York: Routledge.

Stopford, Martin (2008): Maritime economics. Third edition. London, New York: Routledge.

Suez Canal Authority (2015): Rules of Navigation.

5.1. Quiz - Chokepoints of maritime waterways

To check your knowledge about the maritime waterways, feel free to answer the following question before moving on to the element ports.

6. Ports

The facilities in the maritime transport system are called ports and will be presented to you on the following page.

There are several logistics requirements on seaports which are shown in the figure "Logistics requirements on seaports".

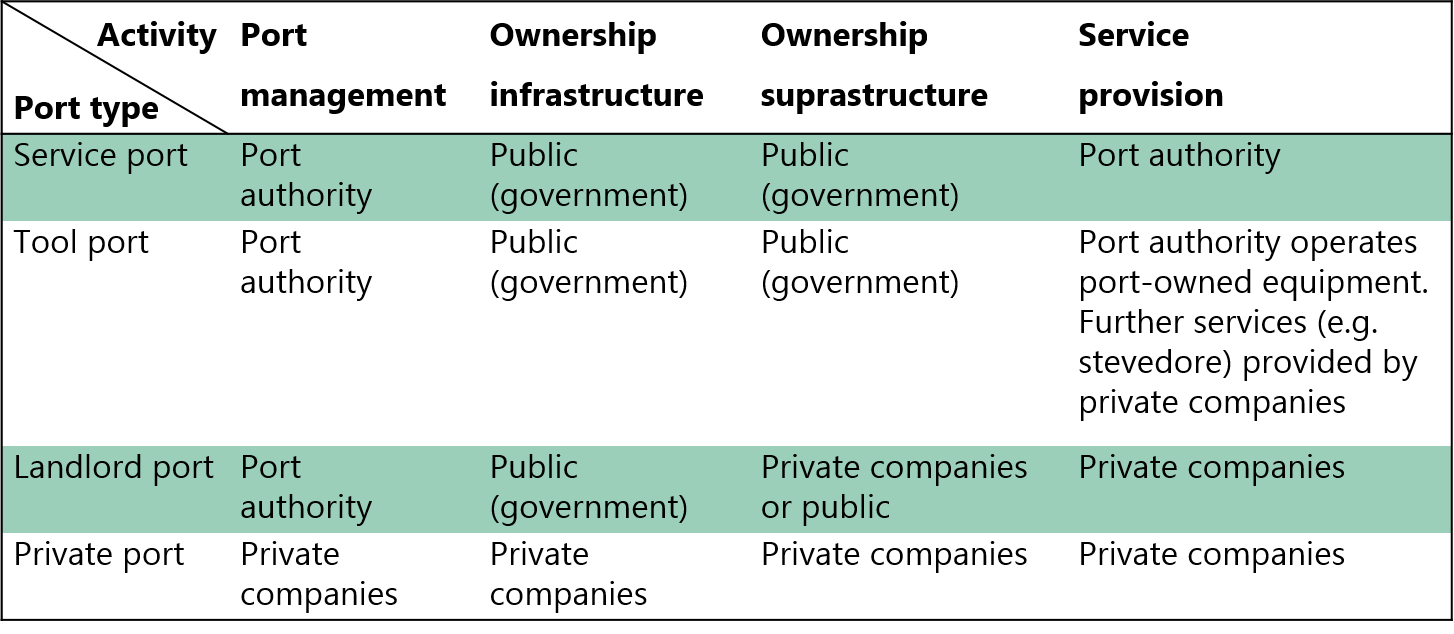

There are different port types, which can be differentiated depending on the responsible stakeholder for the port management, ownership management, ownership suprastructure and service provision. The four port types service port, tool port, landlord port and private port are described in the figure "Different kind of ports".

Container Terminal

Rail-Mounted-Gantry-Crane (RMG):

Straddle carrier:

- packing hall

- empty container depot

- maintenance hall

As you learned before, there are different kinds of vessels for different kinds of goods. Same as for the vessels, besides the already presented container terminals, there are also other kind of terminals in maritime transport.

Ro-Ro terminals:

The relation between ports and goods is called accession.

Accession

Literature

Brinkmann, Birgitt (2005): Seehäfen. Planung und Entwurf. Berlin, Heidelberg: Springer.

Flämig, H., Sjöstedt, L., Hertel, C. (2002): Multimodal Transport: An Integrated Element for Last-Mile-Solutions? Proceedings, part 1; International Congress on Freight Transport Automation and Multimodality: Organisational and Technological Innovations. Delft, 23 & 24 May 2002. (modification of Sjöstedt 1996)

Schönknecht, A. (2009): Maritime Containerlogistik. Leistungsvergleich von Containerschiffen in intermodalen Transportketten. Berlin, Heidelberg: Springer Berlin Heidelberg (VDI-Buch).

Talley, W. (2009): Port economics. 1. publ. London: Routledge.

6.1. Quiz - Container terminal and equipment

7. Summary

In order to sum up this section, the advantages and disadvantages of the maritime transport system are presented to you on this page.

Advantages

- ability to carry high capacity of weight at low freight rates

- large loading space

- supply of special ships

- inflexibility

- dependency on weather conditions (storm, hurricane, ice,...)

- in line dependency on fixed route using container line services

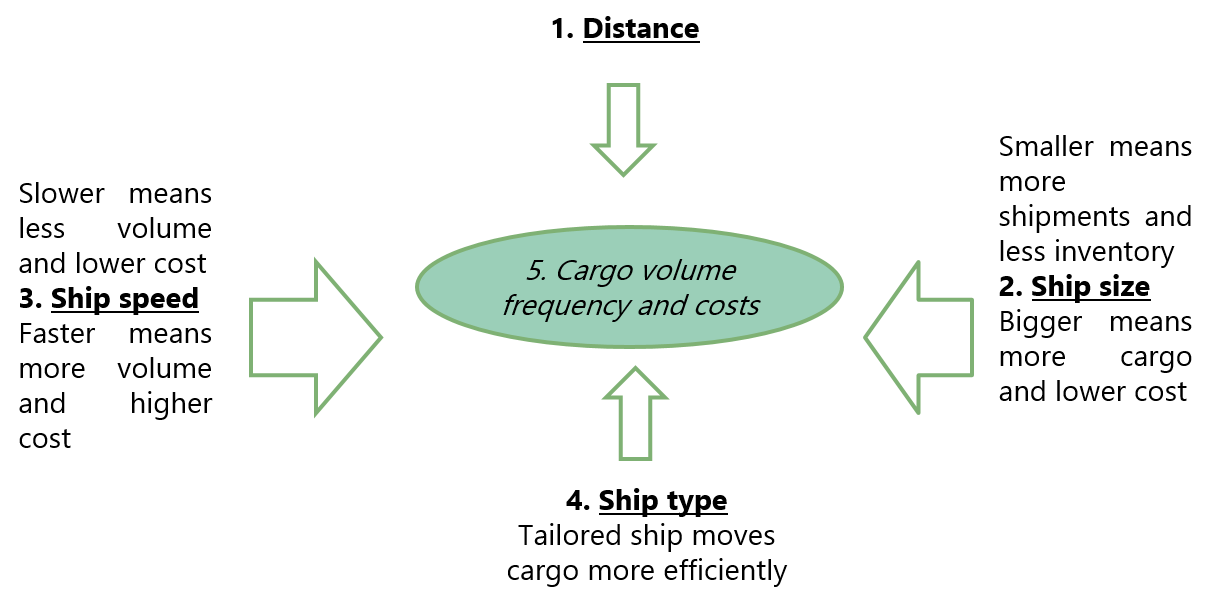

Optimization in maritime transport is possible through the four core variables driving the maritime logistics model: distance, ship size, ship speed and ship type.

Literature

Stopford, M. (2008): Maritime economics. Third edition. London, New York: Routledge.

8. Literature

Biebig, P.; Althof, W.; Wagener, N. (2008): Seeverkehrswirtschaft: De Gruyter Oldenbourg.

Branch, A. (Hg.) (1996): Elements of Shipping. London.

Brinkmann, Birgitt (2005): Seehäfen. Planung und Entwurf. Berlin, Heidelberg: Springer.

DSV (2023): Break Bulk. URL: https://www.dsv.com/de-de/unsere-loesungen/transportarten/seefracht/breakbulk (last access: 08.05.2023)

Heidenblut V., Hompel M. (2011): Taschenlexikon Logistik

International Forwarding Association (2019): Types of Cargo Shipped by Sea Freight Transport. URL: https://ifa-forwarding.net/blog/sea-freight-in-europe/types-of-cargo-shipped-by-sea-freight-transport/ (last access: 08.05.2023)

ISO (1999): ISO 830:1999-09. Beuth-Verlag, Berlin, 1999.

ISO (2013): DIN EN ISO 6346/A3:2013-03, ISO-Container-Kodierung, Identifizierung und Kennzeichnung. Beuth-Verlag, Berlin, 2013.

Hapag Lloyd (2016): Container Specification. URL: https://www.hapag-lloyd.com/content/dam/website/downloads/press_and_media/publications/15211_Container_Specification_engl_Gesamt_web.pdf (last access: 30.03.2022).

Faber, J.; Nelissen, D.; Hon, G.; Wang, H.; Tsimplis, M. (Hg.) (2012): Regulated Slow Steaming in Maritime Transport. An Assessment of Options, Costs and Benefits.

Flämig, H., Sjöstedt, L., Hertel, C. (2002): Multimodal Transport: An Integrated Element for Last-Mile-Solutions? Proceedings, part 1; International Congress on Freight Transport Automation and Multimodality: Organisational and Technological Innovations. Delft, 23 & 24 May 2002. (modification of Sjöstedt 1996)

Ihde, G. (2001): Transport, Verkehr, Logistik. Gesamtwirtschaftliche Aspekte und einzelwirtschaftliche Handhabung. 3., völlig überarb. und erw. Aufl. München: Vahlen (Vahlens Handbücher der Wirtschafts- und Sozialwissenschaften).

Jansson, J. O.; Shneerson, D. (1987): Liner Shipping Economics. Dordrecht: Springer Netherlands.

Jünemann, R. (1989): Materialfluss und Logistik. Systemtechnische Grundlagen mit Praxisbeispielen. Berlin, Heidelberg, New York, London, Paris, Tokyo, Hong Kong: Springer (Logistik in Industrie, Handel und Dienstleistungen).

Marvest GmbH (2021): Massengutfrachter. URL: https://www.marvest.de/magazin/schiffe/massengutfrachter/ (last access: 30.03.2022).

Panama Canal Authority (2022): How does it work. URL: https://pancanal.com/en/history-of-the-panama-canal/#howdoesitwork (last access: 30.03.2022).

Pawlik, T. (1999): Seeverkehrswirtschaft. Internationale Containerlinienschifffahrt Eine betriebswirtschaftliche Einführung. Wiesbaden: Gabler Verlag (Springer eBook Collection Business and Economics).

Rodrigue, J. (2020): The geography of transport systems. Fifth edition. London, New York: Routledge.

Schönknecht, A. (2009): Maritime Containerlogistik. Leistungsvergleich von Containerschiffen in intermodalen Transportketten. Berlin, Heidelberg: Springer Berlin Heidelberg (VDI-Buch).

Schulte, C. (1991): Logistik. Wege zur Optimierung des Material- und Informationsflusses. Verlag Franz Vahlen, München.

Shelter Training Academy (2021): Vessel Traffic Management Information System (VTMIS). URL: https://sheltermar.com/vts/vtmis/ (last access: 30.03.2022).

Stopford, M. (2008): Maritime economics. Third edition. London, New York: Routledge.

Suez Canal Authority (2015): Rules of Navigation.

Talley, W. (2009): Port economics. 1. publ. London: Routledge.

Transway Internationale Spedition GmbH (2021): Informationen zu Schwergutfrachter. URL: https://spedition-seefracht.de/de/lexikon/schwergutfrachter (last access: 13.12.2021).

Veenstra, A. (2005): Empty container reposition: the port of Rotterdam case. In: Simme Douwe P. Flapper, Jo A.E.E. van Nunen und Luk N. van Wassenhove (Hg.): Managing Closed-Loop Supply Chains. Berlin, Heidelberg: Springer Berlin Heidelberg, S. 65–76.

Voth, M. (Hg.) (2001): Speditionsbetriebslehre. Herne.