4. Insects as protein source

4.1 How does it work?

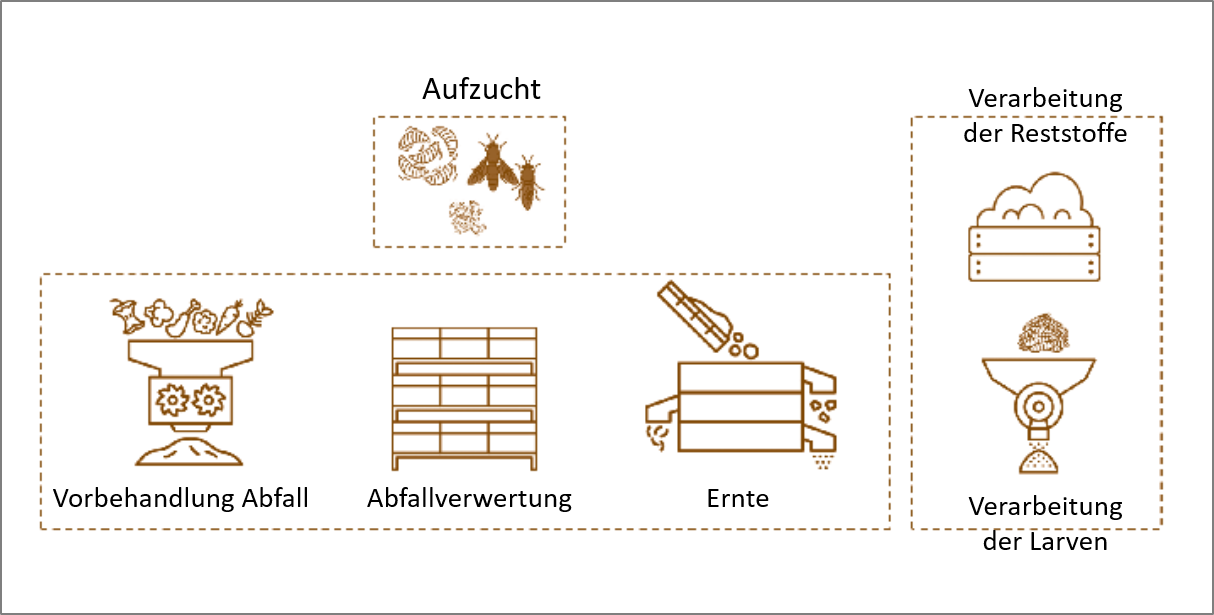

Using the example of the black soldier fly (Hermetia illucens), the method of rearing and further processing will be explained. A detailed description of the process can be found in Dortmans et al. (2021).

The advantage of this fly species is that the larvae prefer to feed on organic residues and are therefore very well suited for the utilization of waste from the food industry. Their larvae have a high protein (35 %) and fat (30 %) content. No highly specialized and expensive technological equipment is required for breeding.

The soldier fly is found in tropical and subtropical regions. The larva develops within 14-16 days. The finished flies do not feed and only live for about a week, during which they mate and lay eggs again.

The following conditions should be created for breeding:

- sufficiently warm: 24-30 °C

- no direct solar radiation

- sufficient water content of fodder: 70-80 %

- sufficient nutrient content in fodder: protein rich and high share of easily accessible carbohydrates, no toxins

- sufficiently chopped fodder

Shortly before pupation, when the larvae have reached their maximum weight, they are harvested. The waste residues and the larvae must be separated from each other. If the material is dry, this can be done by sieving, for example. The live larvae can already be sold as animal feed. If they are sold dead or processed further, they must first be cleaned and disinfected. This is done briefly with hot water, which kills the larvae. They must then be quickly processed into oil, flour or pellets so that they do not spoil.

The following methods can be used for the extraction of proteins:

Subcritical water extraction

- is carried out at temperatures between 100 and 374ºC

- Water is kept in a liquid state by pressure changes

- the density and viscosity of the water decreases and the hydrogen bonds are weakened

- Water now acts as an organic solvent and promotes depolymerization and the formation of smaller soluble protein fractions and amino acids

Dry fractionation

Cleaning, grinding, breaking up the cells and subsequent separation of starch particles and proteins according to their size difference and density

Alkaline extraction

Treatment in the alkaline range (e.g. sodium hydroxide) breaks down the cell wall and extracts the protein. The extractability of proteins is influenced by the ratio of biomass to solvent, temperature, time and pH value.

The following methods can be used for the extraction of fats:

Folch extraction

By adding chloroform and methanol in a ratio of 2:1, the proteins precipitate. The liquid phase contains the lipids. They are then obtained by centrifuging and aspirating the lighter upper phase with the solvent.

Further possibilities:

- Soxhlet extraction

- Supercritical CO2- Extraktion