4.5 Assessment of Hydrogen Applications

Assessment

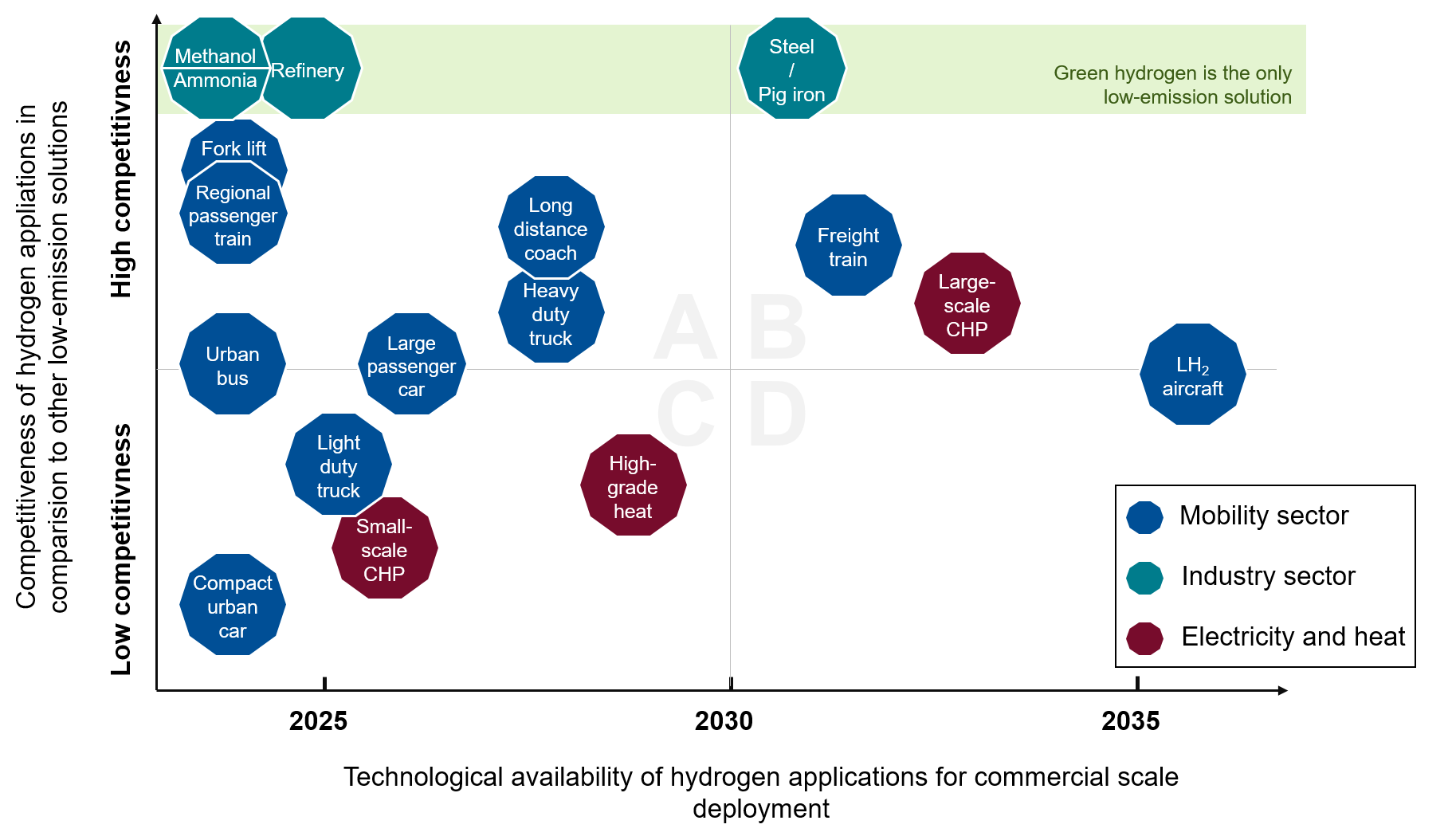

When assessing whether hydrogen applications will play a significant role in certain applications in the near future, two questions are of particular importance:

- Are hydrogen-based applications technologically available on the scale and in the quantity required?

- Are hydrogen-based applications the most economical alternative compared to applications using other low-emission energy carriers?

The figure below gives an overview of the technological availability and economic viability of the most important use cases for green hydrogen.

Because of these advantages in terms of propulsion efficiency and fuel costs, it makes sense to deploy BEVs wherever feasible. However, a reasonable, economical use of BEVs is limited in certain areas of the transport sector by some technical aspects:

- Due to their low energy density, batteries become very large, heavy and expensive when long ranges are required.

- The transport of heavy loads leads to a high energy demand and correspondingly large, heavy and expensive batteries, too.

- The larger the battery storage, the longer the time needed to refuel/charge the BEV.

Gaseous compressed hydrogen has a significantly higher energy density than the lithium-ion batteries currently used in BEV - both gravimetric and volumetric. In addition, hydrogen pressure tanks can be scaled up much more easily and cost-effectively. As a result, in applications where large loads have to be transported over long distances, FCEV might compensate the initial competitive disadvantage versus BEV. This is true, for example, for passenger trains, for which FCEVs are already available today, heavy-duty trucks, for which both BEV and FCEV will enter the market in the next few years, and long-distance coaches.

Since the refuelling with hydrogen only takes a few minutes, FCEV can also be an economical alternative for mobility applications where long idle times (which are required for BEV charging) result in lost earnings. Examples of this are, again heavy-duty trucks in the freight forwarding sector, taxis and intralogistics vehicles like fork lifts.

The applications in the industrial sector shown in the figure above and discussed in Section 4.3 are a special case insofar as the use of green hydrogen is the only currently foreseeable completely greenhouse gas-free solution here. This is mainly due to the fact that the use of the substance properties of hydrogen is in the focus here. Assuming that Germany achieves its goal of greenhouse gas neutrality, there is no alternative to the use of green hydrogen in these sectors. For a timely use of hydrogen in the industrial sector, the crucial factor is therefore how high the additional hydrogen supply costs are compared to fossil raw materials.

Unlike the transport sector, where the cost of fossil fuels (e.g., diesel, gasoline or kerosene) is relatively high, the industry relies on very low prices for fossil raw materials, especially coal and natural gas, to compete on the international market. Accordingly, green hydrogen must also be available at a correspondingly low price so that industry can offer its (then green) products without exorbitant additional costs. For example, the price of hydrogen would have to be between 1 and 2 €/kg for green direct-reduced steel to be produced at roughly the same cost as conventional steel. In heavy-duty transport (trucks, trains, busses), on the other hand, it would be sufficient if green hydrogen were available for 5 to 6 €/kg to ensure that the fuel costs of FCEVs do not exceed those of current diesel vehicles.

Since the refuelling with hydrogen only takes a few minutes, FCEV can also be an economical alternative for mobility applications where long idle times (which are required for BEV charging) result in lost earnings. Examples of this are, again heavy-duty trucks in the freight forwarding sector, taxis and intralogistics vehicles like fork lifts.

The applications in the industrial sector shown in the figure above and discussed in Section 4.3 are a special case insofar as the use of green hydrogen is the only currently foreseeable completely greenhouse gas-free solution here. This is mainly due to the fact that the use of the substance properties of hydrogen is in the focus here. Assuming that Germany achieves its goal of greenhouse gas neutrality, there is no alternative to the use of green hydrogen in these sectors. For a timely use of hydrogen in the industrial sector, the crucial factor is therefore how high the additional hydrogen supply costs are compared to fossil raw materials.

Unlike the transport sector, where the cost of fossil fuels (e.g., diesel, gasoline or kerosene) is relatively high, the industry relies on very low prices for fossil raw materials, especially coal and natural gas, to compete on the international market. Accordingly, green hydrogen must also be available at a correspondingly low price so that industry can offer its (then green) products without exorbitant additional costs. For example, the price of hydrogen would have to be between 1 and 2 €/kg for green direct-reduced steel to be produced at roughly the same cost as conventional steel. In heavy-duty transport (trucks, trains, busses), on the other hand, it would be sufficient if green hydrogen were available for 5 to 6 €/kg to ensure that the fuel costs of FCEVs do not exceed those of current diesel vehicles.